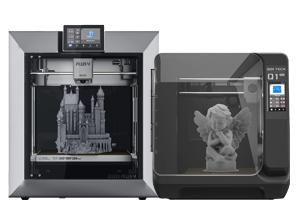

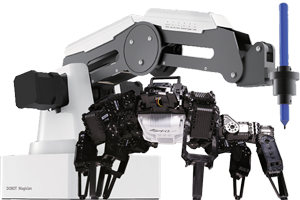

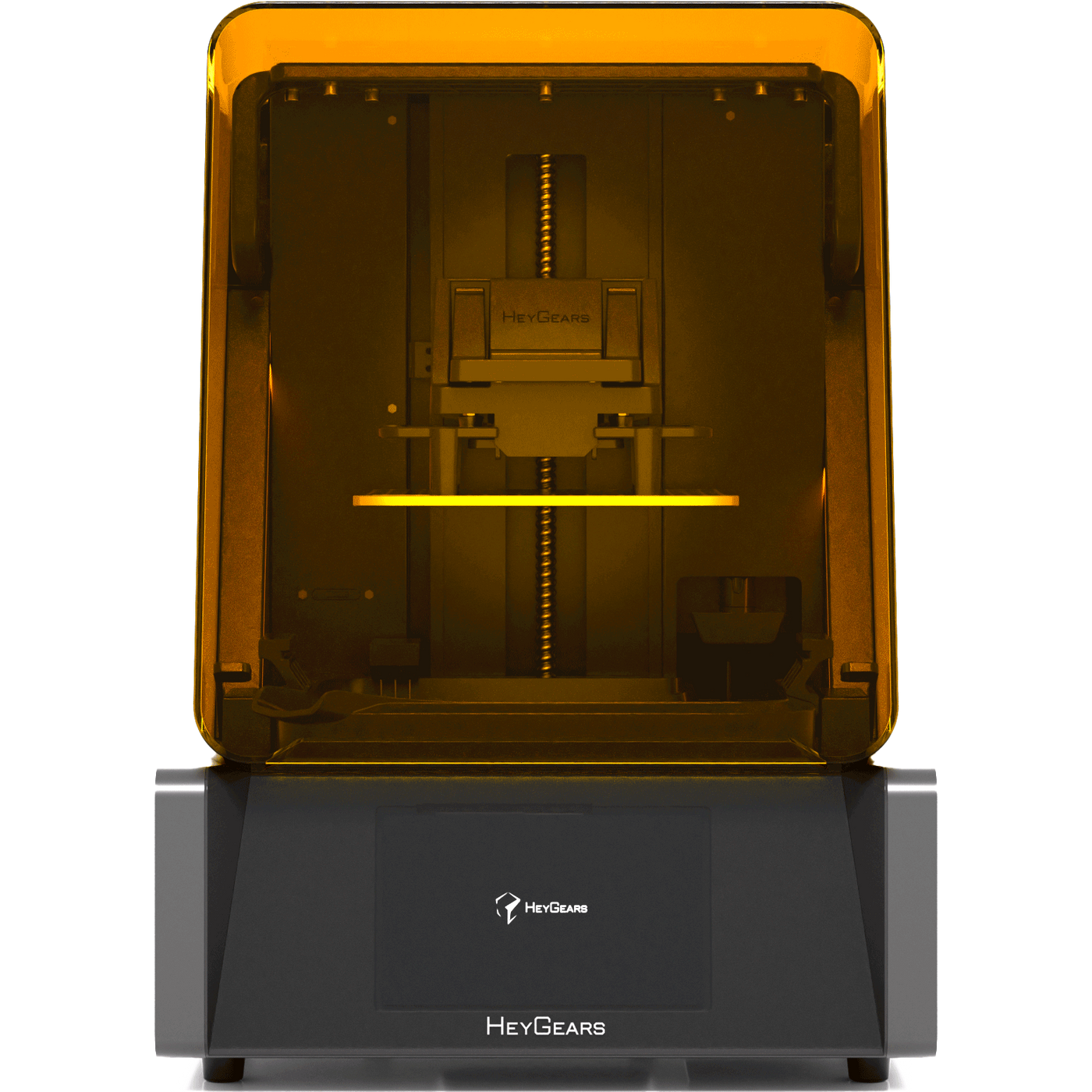

Introducing the Kevvox SP Series high performance professional desktop 3d printers with fully integrated sophisticated software. Based on DLP technology these printers boast superior quality precision parts with a up to 10 micron layer resolution.

Professionals such as jewellers, product designers, dentists, architects, toy makers and medical equipment manufacturers; indeed anyone that requires economically viable, high quality 3D printed parts, can now bring 3D printing into their studios and offices.

Kevvox desktop 3D printers produce professional, industrial-grade, high quality parts that are economically viable. Furthermore, within professional environments Kevvox 3D printers fit comfortably in the workflow in terms of being office friendly and easy to use.

Some of the other key features of the Kevvox 3D printing systems include their robust nature, original materials, they are easy to install and maintain in an office environment and they add value in some unique ways.

The R&D conducted for the Kevvox 3D printers identified some key gaps in the existing 3D printer market. The biggest pain point identified and resolved - is the need for integrated software, which simplifies the overall design-to-print process greatly, adds value without increasing costs and brings simply amazing results.

Breakthrough features:

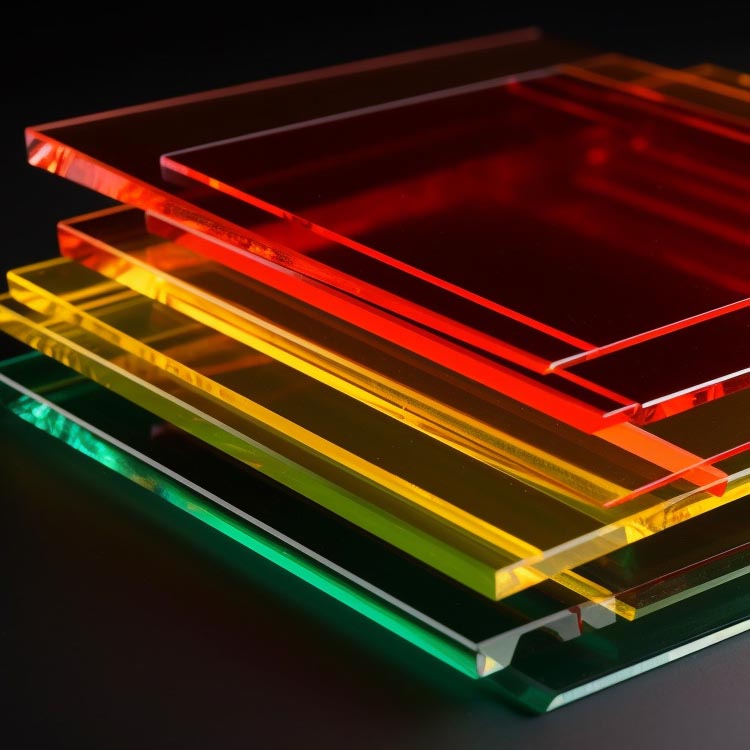

• Unique range of proprietary materials.

• Full control over light intensity for each of the different materials, as each material has different power requirements for the hardening process.

• Full material temperature control to ensure the highest quality print every time.

• A colour LCD that allows the user to follow the entire printing job, as it progresses, from start to finish.

• Large internal memory that can store the entire job, with no requirement for the computer to be connected after the job is sent to the machine.

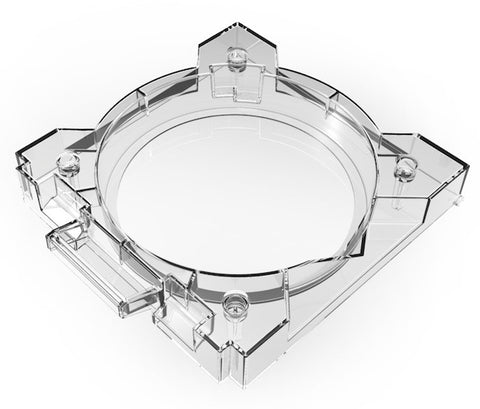

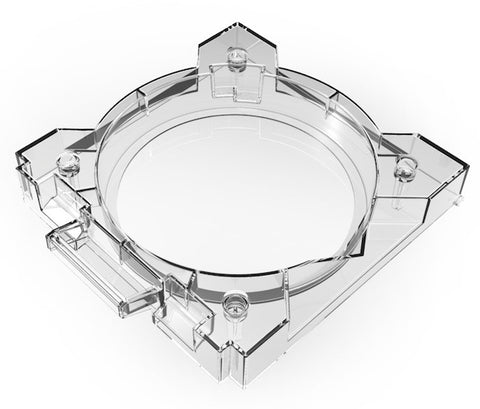

• A proprietary ‘Zero waste’ tray that lasts longer than comparable models and avoids wasted material.

• True plug & play system via USB.

• High-precision mechanical parts for maximum accuracy, with no user calibration required.

• Blue LED technology that can print for over 50,000 hours without changing the light source.

Kevvox SP 3D printers are stand-alone systems, based on DLP technology, that fit comfortably into any design or engineering environment. There are two Kevvox SP Series models — the SP4300 and the SP6200.

These offer 2 different build volumes, 56x35x100mm (2.20″ x 1.38″ x 3.94″) and 80x50x100mm (3.15″ x 1.97″ x 3.94″) respectively. The SP4300 can print down to a resolution of 43 µm (0.0017″), while to SP6200 offers 62 µm (0.0024″). There is also a choice of proprietary materials with more in development. 2 sizes of printing area on the machine.

Additional Features:

• The best surface for tray that shortens the cleaning time.

• Trays can rest on normal flat surfaces, unlike other printer trays that need extra care to prevent scratches underneath.

• Trays are stackable, and of space-saving design.

• Resins can be left overnight under cold temperatures without fear of it sticking permanently to the tray.

• Built-in heating element ensures cold resin is brought up to the required temperature, for efficient and error-free printing.

• Flip-up door for easy user access.

• Broad access area when removing printed parts from the printer.

• Pause & Resume function on printer.

• Overnight printing with auto-off function.

• True desktop size, low noise and can be easily housed within existing facilities.

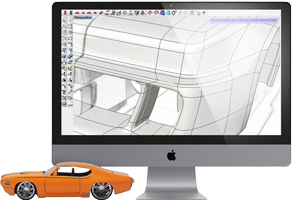

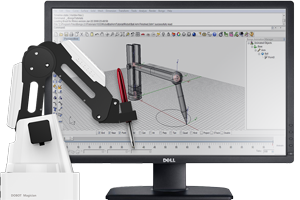

Software K-Studio

While you may think that you have heard this ‘new’ 3D printer story before — it has always been focused on the 3D printer itself. And while the R&D effort into the Kevvox 3D printer has been extensive, the team has placed equal emphasis on the development of complementary, integrated software. And it is this together with the high resolution and the affordable price that TRULY sets this 3D printer apart.

The Kevvox R&D team has developed sophisticated and yet easy to use software for 3D printing. Incorporating an extremely simple and intuitive user Interface, the software offers unprecedented functionality that addresses everything users would expect from a world-class 3D printer.

K-Studio features at a glance:

• K-Studio can manage the entire 3D printing process, including material and jobs.

• Many built-in functionalities that help users to thoroughly prepare the job for the printer.

• K-Studio has extremely user-friendly wizards for ease-of-use.

• K-Studio can save projects for easy sharing or future use.

• Fully integrated with all Kevvox 3D printers, which bring huge cost savings.

• High performance and speed.

• Automatic and manual repair tools for object issues such as fix gaps and holes, unify all shells, remove intersections and overlaps, invert normals and many more.

• Automatic and manual advanced support generation.

• Ability to work with multiple 3D Printers at same time.

• Ability to work with multiple materials.

• Advanced object editing tools such as make-objects-hollow, create-holes, reduce-number-of-triangles, merge-objects and many more.

• Ability to slice and export the objects.

• Full object analysis.

• Easy, intuitive placement and orientation of objects on the platform for best build.

• Ability to work with different kinds of metric systems.

Why fixing .stl files is important?

.stl is one of the most common output formats generated by most 3D design packages for 3D printing and additive manufacturing applications. It is widely recognised that the .stl files generated by most 3D software is riddled with issues, that often require skill and a great deal of time to resolve. Often, these issues are not even visible to the naked eye as they are microscopic in nature. If they remain unresolved, they can seriously impact the quality of the final 3D printed part.

The Kevvox R&D team knew that this was a critical problem to resolve with the Kevvox 3D printers and they have tackled the issue head on. As a result, they have developed a built-in solution for defective .stl files — K-Studio — that will automatically fix any issues in the file before processing it for final 3D printing. This offers users a huge improvement in the precision that Kevvox 3D printers deliver.

Technical Specifications:

|

Model no.

|

Kevvox SP4300

|

Kevvox SP6200

|

|

Build Size (L x W x H)

|

56 x 35 x 100mm

|

80 x 50 x 100mm

|

|

Native Pixel Size (x,y)

|

43 mircons

|

62 microns

|

|

Layer Resolution (z)

|

10,25,50 or 100 microns

|

10,25,50 or 100 microns

|

|

K-Studio Software Included

|

Yes

|

Yes

|

|

Machine Dimensions(L x W x H)

|

375 x 425 x 470mm

|

375 x 425 x 470mm

|

|

Nett Weight

|

17kg

|

17kg

|

Materials Avaialble:

| ABS-Like (ABS-LC100) |

| Wax-Like (WAX-LC200) |

| High-Temperature Resistant (HTR-LC300) |

|