Your Cart is Empty

We gladly accept school purchase orders!

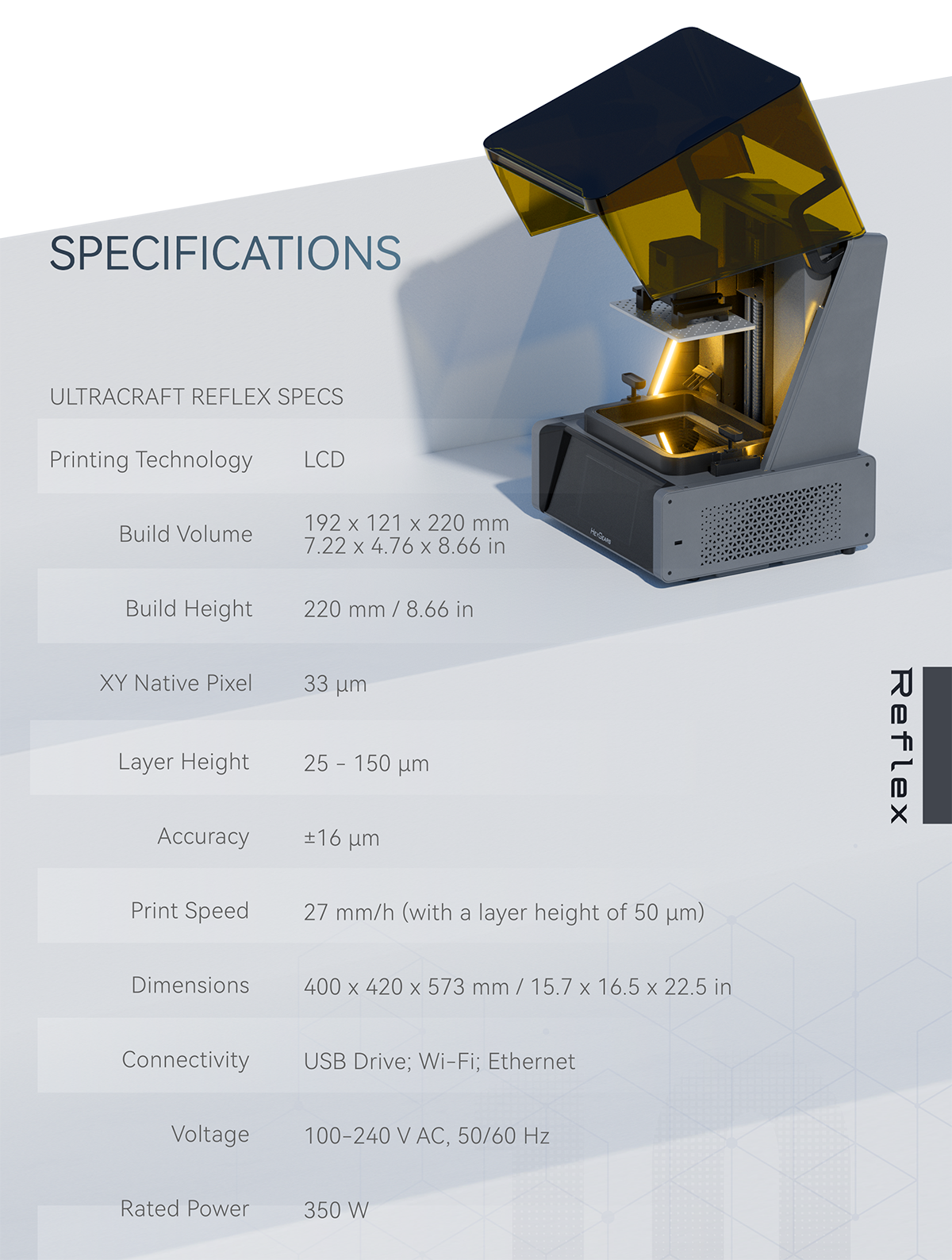

HeyGears UltraCraft Reflex Combo is designed to make resin 3D printing a worry free process. Powered by AI algorithms and an automated process you can achieve professional commercial grade results with ease.

HeyGears has produced an all-in-one production platform enabling users to actualise ideas faster and materialize them. Its advanced features and capabilities make this resin 3D printing solution innovative and efficient in streamlining the production process towards the final outcome.

The printer’s advanced features and intelligent AI algorithms assure smoother surfaces and stable performance, akin to injection molded-like final results. Users can anticipate next-level surface quality and fine details for their prints. The UltraCraft Reflex also showcases industrial-grade hardware, ensuring durability and reliability for every print.

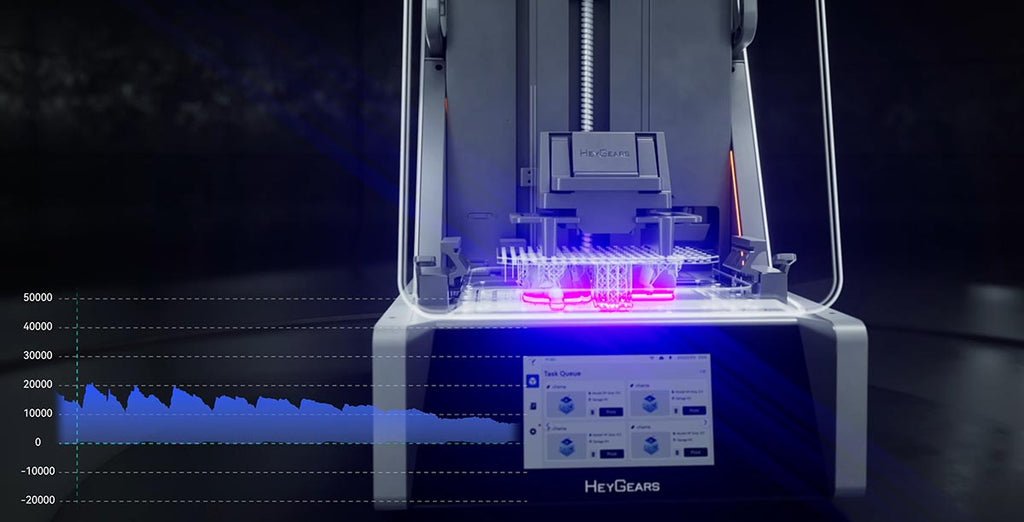

Additionally, the product’s SmartAI peeling force management significantly increases print success rates with consistent results.

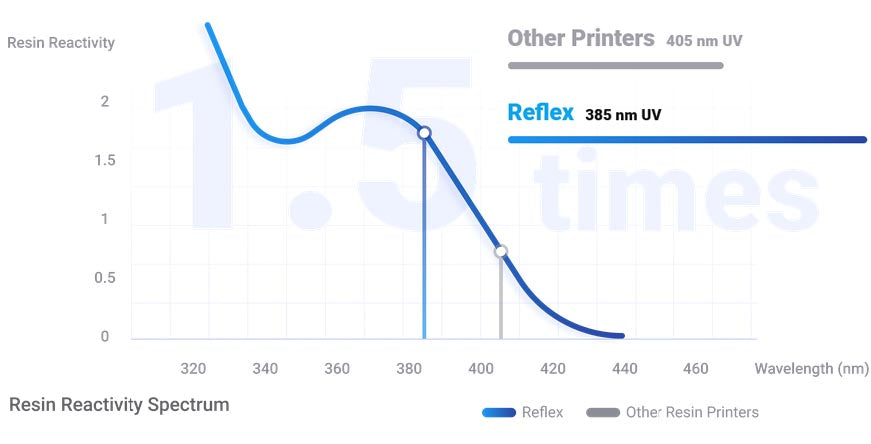

With unmatch print results HeyGears’ self-developed TrueUV 385nm+ 3D printing resins provide users with the greatest performance for their final print results.

The Ultraflex ultilises professional grade 385nm UV resins. This provides a 1.5x more powerful curing effect enabling superior detail reproduction, smoother surface finish, better physical and mechanical properties and dimensional accuracy.

Materials can not only be used to produce protoypes but for mass production of finished products.

The UltraCraft Reflex achieves higher than injection molded dimensional accuracy and wear resistance compared to consumer grade 405nm resin printers.

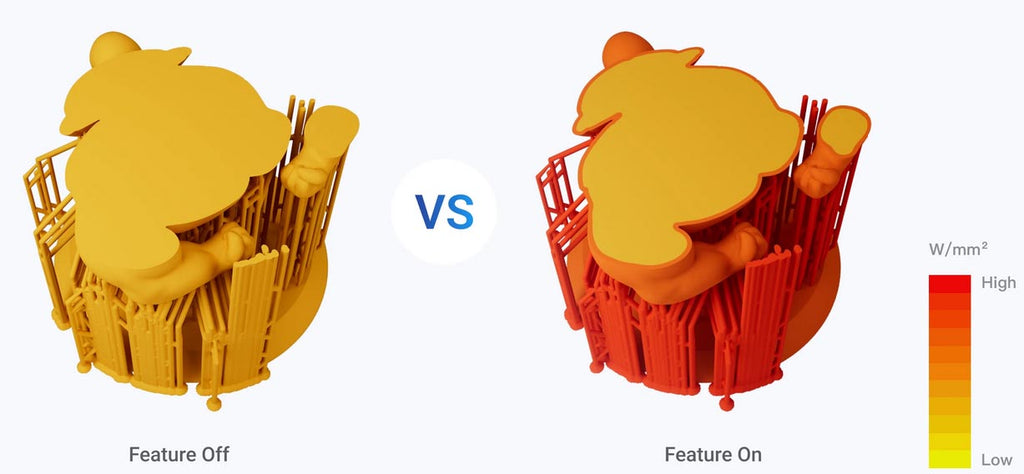

A game changer in MSLA resin print quality and accuracy is the ability for HeyGears 3D printers to isolate exposure times to different regions of each layer. This ensures maximum detail and dimensional accuracy of the part, maximum strength of support structures whilst maintaining minimal peeling force between layers.

SmartAI peeling force monitoring and management automatically applies the optimal peeling parameters to each printed layer to improve printing efficiency and results by detecting characteristics of the sliced layer and calculating the results of using different peeling forces.

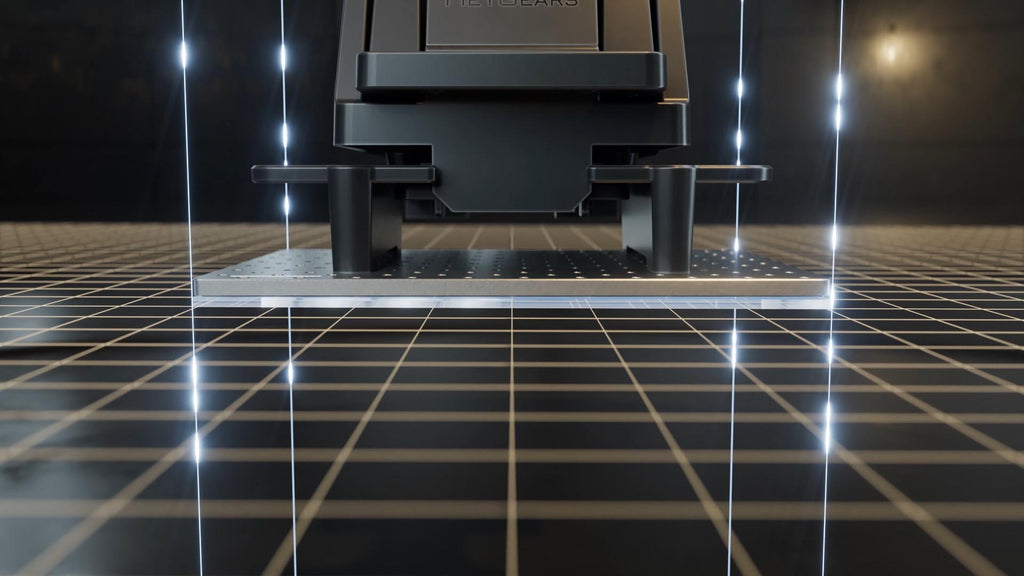

The UltraCraft Reflex is easy to set up and start printing, with Intelligent assisted leveling and a floating screen structure, Reflex can automatically level build plate inclinations of up to 0.15° and eliminate gaps between the platform and tray of up to 150 μm.

The UltraCraft Reflex automatically detects which resin is loaded into the printer. A virtual spirit level and resin level sensor automatically fills and monitors the tank, ensuring a consistent level is maintained. within ±5 grams during printing.

Resin exposure and dimensional variation of printed parts are greatly effected by environmental variations.

The temperature of the resin inside the tray is monitored and automatically heated. This feature alleviates any concerns regarding resin uniformity and ensures consistency and dimensional accuracy of printed parts.

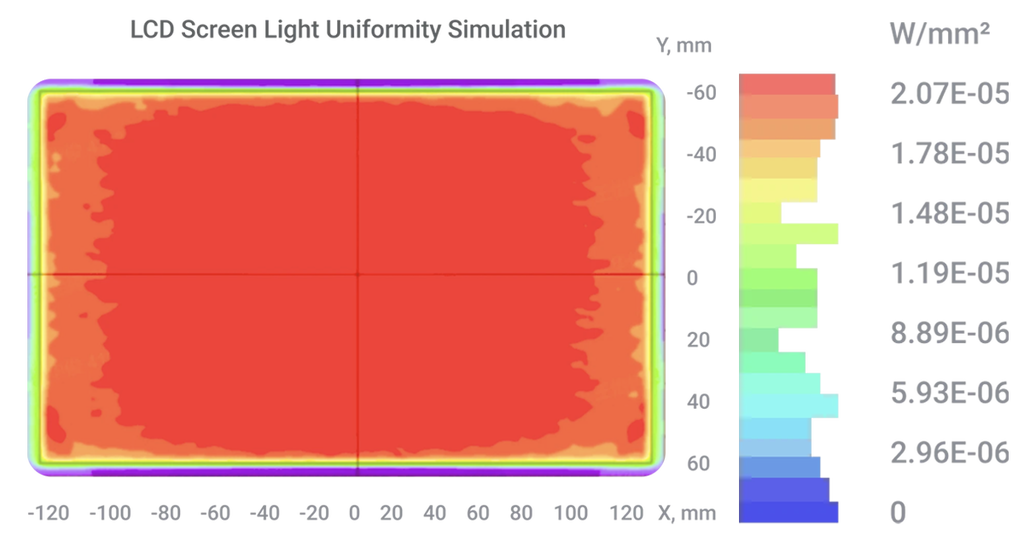

High dimensional accuracy and tolerances of parts are achieved through consistent light uniformity across the LCD screen.

Ideal for the production of batch production of consumer products. The UltraCraft Reflex can achieve repeatable production of identical parts.

The UltraCraft Reflex can achieve ultra fine detail and is able to print details as precise as 0.136 mm

Better than injection molding dimensional accuracy

Ideal for the production parts and prototyping the UltraCraft Reflex can achieve Zero Tolerance fitment of mating parts.

*Test with UltraPrint PARP10 Rapid Prototyping Resin

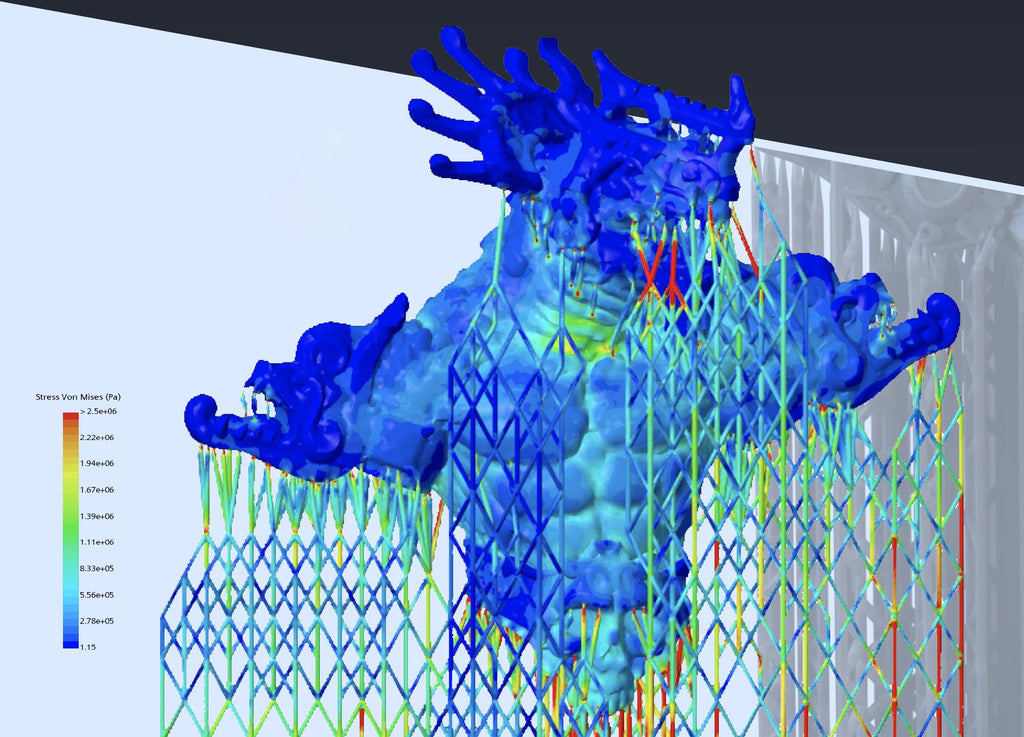

Support structures are easy to remove, even on large compex models.

WIth inteligent algorithims- scafford supports are automatically generated and optimised based on the resin used and the peel forces.

PAT10 is ultra clear with a glass like 88% Transparency.

It is a engineered to be strong and stable resin and is highly yellowing resistant.

Any color combination can be used to obtain a consistent print with high accuracy and performance. The printing process with this material is stable and has consistently successful results.

PAM10-is a collection of 5 colour resins. When mixed in any combination the print results are remain dimensionally and mechanically consistent.

Ideal for artistic applications and skin-friendly production parts.

UltraCraft Pulsing Release Module boosts your production efficiency by reducing approximately 50% of the peeling force for each layer through high-frequency vibrations during printing.

The benefits include a 20% fasterprinting speed*, 25% fewer supports*, 70% reduction in contact point area, allows steeper overhangswithout supports, ensures super fine surface detailsand smooth surface finishwithout artifacts.

Additionally there are cost saving by reducing the consumption as well as doubling the hardware longevity of the service life of the tray surface.

The reduction of contact point area significantly reduces the scaring of the surface of the contact points- this significantly improves print quality and reduces post processing time.

The Pulse Release Module shall also unlock the use of more specialised resin property resins (coming soon).