There are a variety of very different types of 3D printing

technologies, but they all share one core thing in common: they create a

three dimensional object creating it layer by successive layer, until

the entire object is complete.

Each of these layers is a thinly sliced, horizontal cross-section of

the eventual object. Imagine a multi-layer cake, with the baker laying

down each layer one at a time until the entire cake is formed. 3D

printing is similar, but just a bit more precise than 3D baking.

It Begins with a Digital File

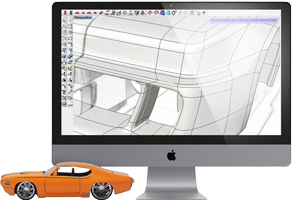

Each 3D-printed object begins with a digital Computer Aided Design

(CAD) file, created with a 3D modeling program, or which was scanned

into a 3D modeling program with a 3D scanner. To get from this digital

file into instructions that the 3D printer understands, software then

slices the design into hundred or thousands of horizontal layers.

The 3D printer reads this file, and proceeds to create each layer

exactly to specification. As the layers are created, they blend

together with no hint of the layering visible, resulting in one three

dimensional object.

Off to the 3D Printer

|

| An Objet 3D Printer and its workflow |

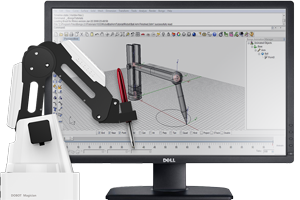

The 3D printer could be a Fused Deposition Modeling (FDM) printer,

somewhat similar to current 2D inkjet printers but with an additional

axis, which deposits droplets of melted material through a nozzle to

form each layer. It could be a selective laser sintering (SLS) printer,

where the object is built up in a bed of powdered material by a scanning

laser beam that fuses bits of the powder together, again, one layer at a

time. Or it could be one of several other technologies.

3D printing is also called “additive manufacturing,” using an

“additive process.” This is as opposed to what is called a “subtractive

process.” To explain the difference, imagine a sculptor chiseling a

block of stone — he chips away until he has the sculpture just as he

wants it, and then throws out what’s been whittled away. He began with

block of material and then subtracted from it. This is a subtractive

process. In the manufacturing world, this is analogous to material being

cut, drilled, milled or machined off. But in additive manufacturing,

the 3D printer doesn’t take anything away — it simply creates each bit

of the object where it needs it, layer by layer, successively, in an

additive process.

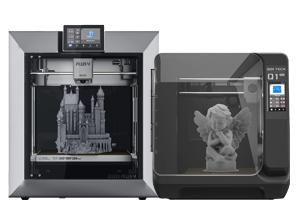

Commercial 3D printers

While most people have yet to even hear the term 3D printing, the

process has been in use for decades. Manufacturers have long used the

printers in the design process, to create prototypes for traditional

manufacturing. But until the last few years, the equipment has been

expensive and slow.

Now, fast 3D printers can be had for tens of thousands of dollars,

and end up saving the companies many times that amount in the

prototyping process. For example, Nike uses 3D printers to create

multi-colored prototypes of shoes. They used to spend thousands of

dollars on a prototype and wait weeks for it. Now, the cost is only in

the hundreds of dollars, and changes can be made instantly on the

computer and the prototype reprinted on the same day.

Some companies are using 3D printers for short run or custom

manufacturing, where the printed objects are not prototypes, but the

actual end user product. As the speeds of 3D printing go up and their

price comes down, look for more and more of this. And expect more

availability of personally customized products.

Personal 3D Printers

A Huxley RepRap 3D printer that has printed out its own parts.

So far we’ve only talked about commercial 3D printers. There is a

whole other world of 3D printers: personal and DIY hobbyist models. And

they are getting cheap, with prices typically in the range of $300 –

$2,000.

The RepRap open source project really ignited this hobbyist market in

the same way the Apple I microcomputer ignited the hobbyist desktop

computer market in the late 1970s. For about a thousand dollars, people

have been able to buy the RepRap kit and put together their own personal

3D printer, complete with any customizations they were capable of

making. And what’s more, these printers print most of the parts for more

printers. Complete self-replication, including electronic circuit

boards, is the goal.

The interest in RepRap spawned scores of other low-cost 3D printers,

both DIY and fully-assembled, and as the prices keep coming down, it

puts 3D printers into more and more and more hands.

But do you have to be an engineer or a 3D modeling expert to create

3D models on your own 3D printer? No, not at all. While complex and

expensive CAD software like AutoCAD and Solidworks have a steep learning

curve, there are a number of other programs, many free, that are very

easy to learn. The free version of Google SketchUp, for example, is very

popular for its ease of use; and the free Blender program is popular

for its advanced features.

If you don’t have your very own 3D printer, not to worry, there are

3D printing service bureaus like Shapeways and Ponoko that can very

inexpensively print and deliver an object from a digital file that you

simply upload to their user-friendly website. It’s almost as easy as

ordering a custom t-shirt from Cafepress or Zazzle.

Even if you don’t design your own 3D model, you can still print some

very cool pieces. There are model repositories such as Thingiverse, 3D

Parts Database and 3D Warehouse that have model files you can download

for free.

What do all these people print? It’s limitless. Some print things

like jewelry, some print replacement parts for appliances such as their

dishwasher, some invent all sorts of original things, some create art,

and some make toys for their kids. With the many types of metal,

plastic, glass and other materials available (even gold and silver),

just about anything can be printed.

3D Printing Methods

Stereolithography (SLA)

3D Systems explains the process of Stereolithography

The first commercially available 3D printer (not called a 3D printer

back then) used the stereolithography (SLA) method. This was invented

in 1986 by Charles Hull, who also at the time founded the company, 3D

Systems. A SLA 3D printer works by concentrating a beam of ultraviolet

light focused onto the surface of a vat filled with liquid photocurable

photopolymer (resin). The UV laser beam draws out the 3D model one thin

layer at a time, hardening that “slice” of the eventual 3D model as the

light hits the resin. Slice after slice is created, with each one bonded

to the other, and next thing you know you have a full, extremely

high-resolution three dimensional model lifted out of the vat. Unused

resin is reusable for the next job.

Fused Deposition Modeling (FDM)

Stratasys explains Fused Deposition Modeling at a trade show

Also invented in the late 1980′s, by Scott Crump, was Fused

Deposition Modeling (FDM) technology. With patent in hand, he and his

wife founded Stratasys in 1988. With FDM, the object is produced by

extruding small beads of melted thermoplastic material to form layers as

the material hardens immediately after it leaves the extrusion nozzle.

It is one of the lesser expensive 3D printing methods. Most FDM printers

print with ABS plastic (think Lego), as well as PLA (Polylactic acid), a

biodegradable polymer, which is produced from organic material.

The actual term “Fused Deposition Modeling” and its abbreviation

“FDM” are trademarked by Stratasys. RepRap uses a similar process, but

has called it “Fused Filament Fabrication” (FFF), so as to not step on

the trademark. With FFF, the material is fed via filament from a spool

of the material.

Selective Laser Sintering (SLS)

3D Systems demonstrates the SinterStation Pro SLS 3D printer

The 1980′s were big for inventing 3D printing technologies. Not only

were SLA and FDM invented and patented then, but so was Selective Laser

Sintering (SLS), by Carl Deckard and colleagues at the University of

Texas in Austin. SLS works similarly to SLA, but instead of liquid

photopolymer in a vat, you’ll find powered materials, such as

polystyrene, ceramics, glass, nylon, and metals including steel,

titanium, aluminum and silver. When the laser hits on the powder, it is

fused at that point (sintered). All unsintered powder remains as is,

and becomes a support structure for the object. The lack of necessity

for any support structure with SLS is an advantage over SLS over SLA —

none to remove after the model is complete, and no extra waste was

created. All unused powder can be used for the next printing.

Other Methods

There are other variants of these technologies. For example there is

Selective Laser Melting (SLM), which is like SLS but fully melts the

power rather than just fusing the powder granules under lower

temperature. This is similar to Electron Beam Melting (EBM) which is

uses an electron beam instead of a UV laser. And then there is a

completely different technology called Laminated Object Manufacturing

(LOM), where layers of adhesive-coated paper, plastic, or metal

laminates are successively glued together and cut to shape with a knife

or laser cutter.

3D Printing is a Game Changer

Instantly printing parts and entire products, anywhere in the world,

is a game changer. But it doesn’t stop there. 3D printing will affect

almost every aspect of industry and our personal lives.

Medicine will forever be changed as new bioprinters actually print

human tissue for both pharmaceutical testing and eventually entire

organs and bones.

Architecture and construction are changing as well. Now, 3D-printed

models of complex architectural drawings are created quickly and

inexpensively, rather than the expensive and time-consuming process of

handcrafting models out of cardboard. And experimental, massive 3D

printers are printing concrete structures, with the goal of someday

building entire buildings with a 3D printer.

Art is already forever changed. Digital artists are creating

magnificent pieces that seem almost impossible to have been made by

traditional methods. From sculptures to light fixtures, beautiful

objects no longer need to be handcrafted, just designed on a computer.

And there are developments where you least expect them: for example,

archeologists can 3D scan priceless and delicate artifacts, and then

print copies of them so they can handle them without fear of breakage.

Replicas can be easily made and distributed to other research facilities

or museums. It has been used to create a full-size reproduction of King

Tutankhamun’s mummy and to repair Rodin’s sculpture, The Thinker.

The Future of 3D Printing

This is a disruptive technology of mammoth proportions, with effects

on energy use, waste, customization, product availability, art,

medicine, construction, the sciences and of course manufacturing. It

will change the world as we know it. Before you know it.

Source: 3dprinter.net