Your Cart is Empty

LARGE-FORMAT, FAST, RELIABLE INDUSTRIAL GRADE 3D PRINTER

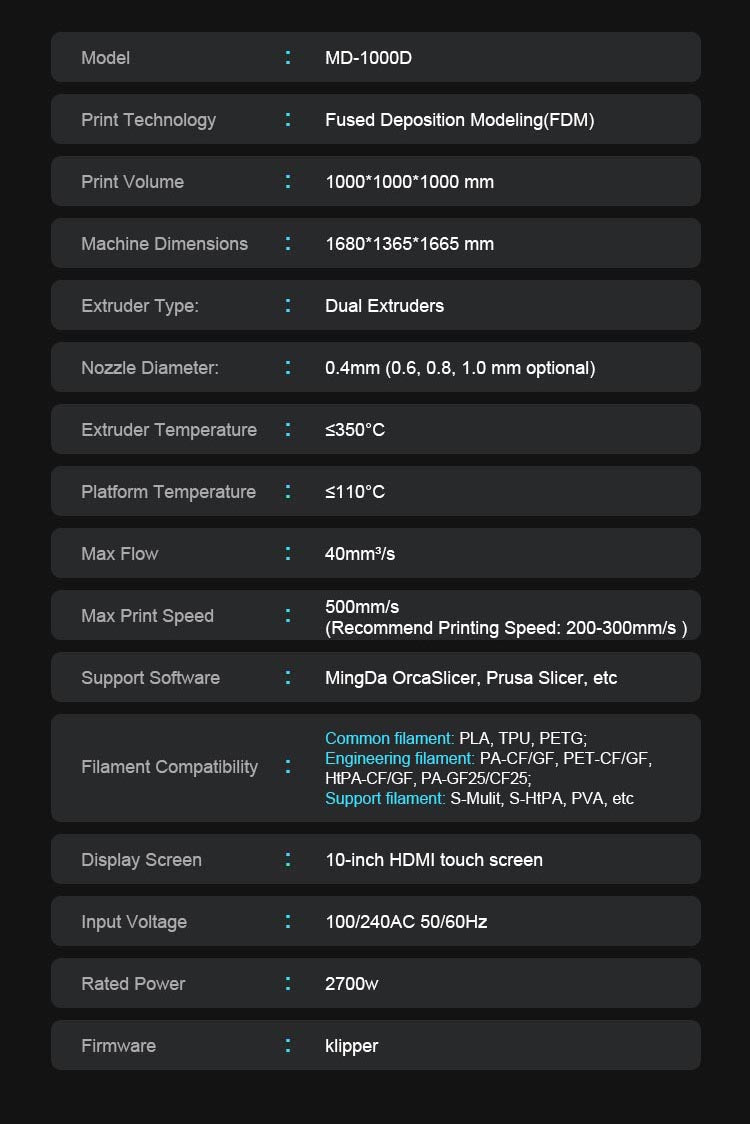

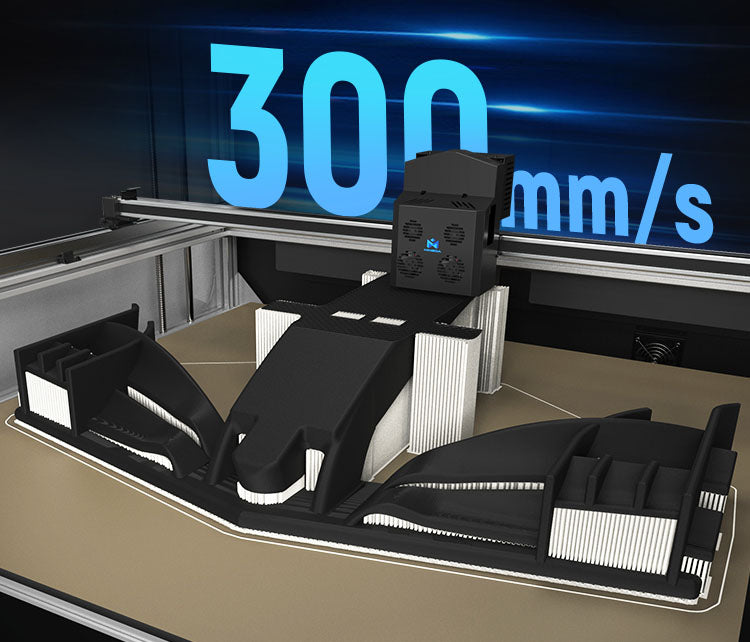

The MD-1000D is high speed enclosed build chamber FFF 3D printer which features a substantial 1m x 1m x 1m build volume, engineered specifically for reliable industrial prints and engineering materials. It boasts closed-loop stepper motors on all axes and retractable dual nozzles. Both hotends reach up to 350°C, allowing for printing high-temperature Nylon filaments in demanding applications. This second nozzle can not only be used for multi-color printing but is often loaded with a support material that easily snaps off the printed parts, so even the most complex prints and prototypes are possible on this machine.

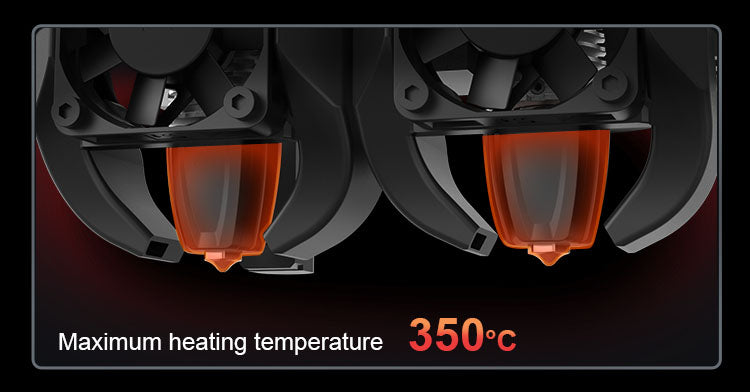

This printer utilises the latest in Klipper ecosytem of 3d printer technology including high 300m/s print speeds, vibration compensation, automated bed leveling and MINGDA world first optical nozzle alignment calibration.

-DOWNLOAD BROCHURE HERE-

A substantial 1m x 1m x 1m print volume. This is not your average, simply upscaled consumer 3D printer since the focus was on ensuring suitability for dependable industrial prints and engineering materials. Fully enclosed, it employs closed-loop stepper motors on all axes.

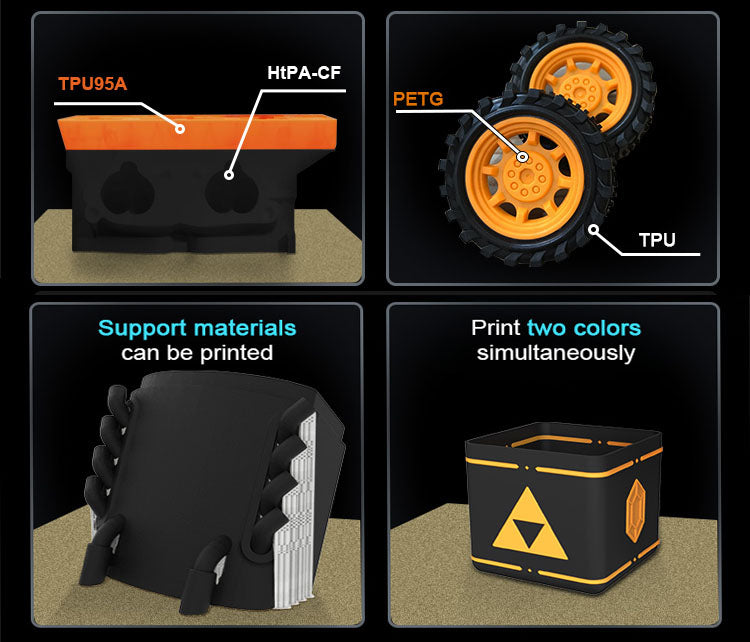

The MD-1000D features retractable dual extruders. This reduces cross contamination of filament ooze ensuring clean multi-material parts.

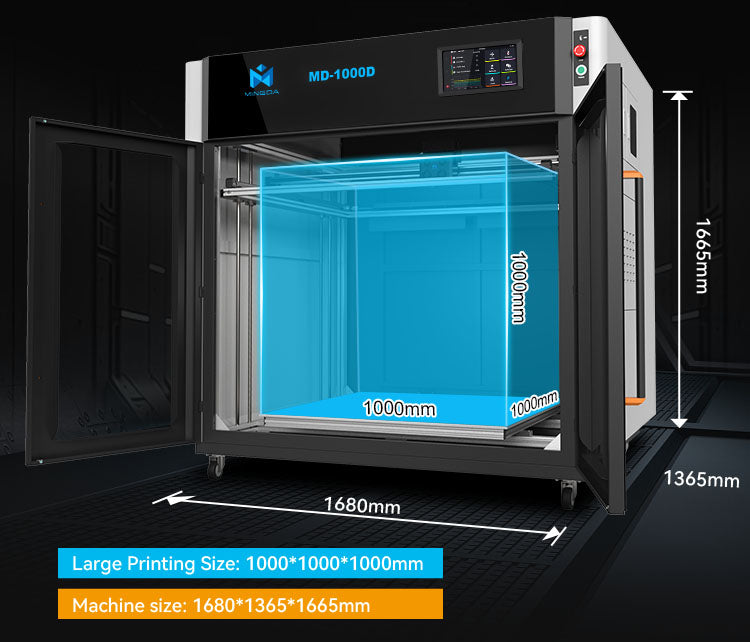

Boasting a class leading high flow rate of 40mm³/s and can print up to 350°C. This enables printing in high strength engineering materials at high speeds.

A revolutionary technology, closed-loop control systems with linear stepper motors provide unparalleled precision, flexibility, and reliability providing accurate and precise control. They operate at high speeds without compromising accuracy, improve print quality and eliminate skipping errors.

Klipper controlled firmware controls high print speeds of 300mm/s & travel speeds of up to 500mm/s with 10000mm/s ²Peak acceleration.

High-speed printing with exceptional print quality is ensured by smart technologies including input shaping and vibration compensation for quality prints.

This combined chassis dampening, robust construction, closed-loop stepper motors on all axis prevent layer shifting.

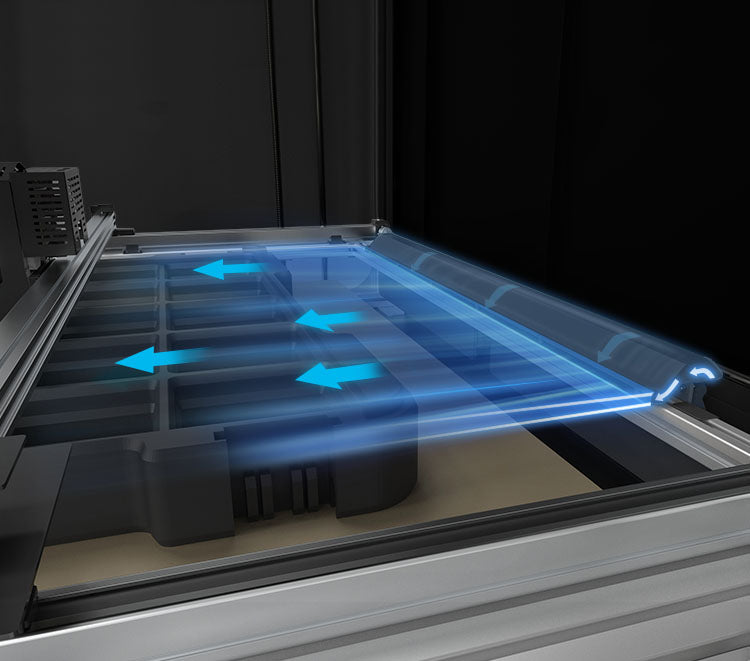

The advanced air flow system truly takes model cooling to the next level with aerodynamic air duct design that blasts models with intensely powerful directed airflow for enhanced cooling capabilities, crafting perfect prints.

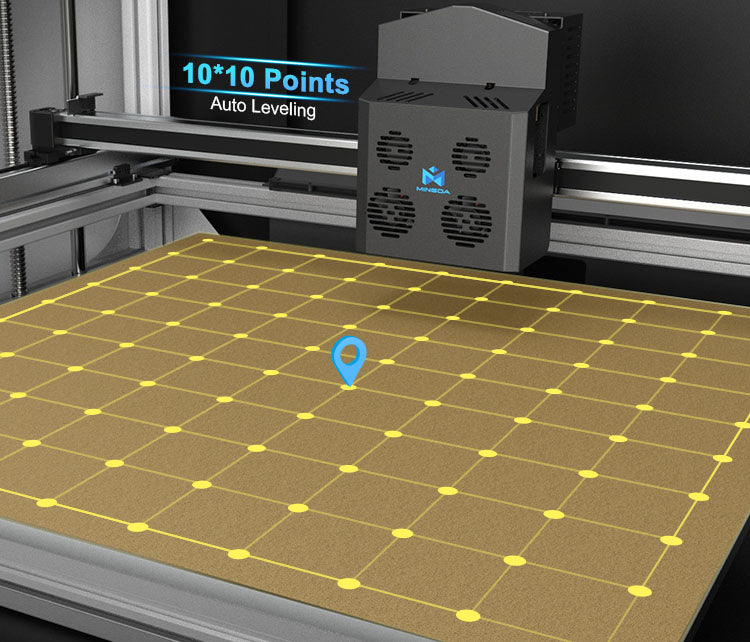

An advanced optical surface scanner measures the topology of the print surface within seconds. Ensuring a high accurate first layer with every print.

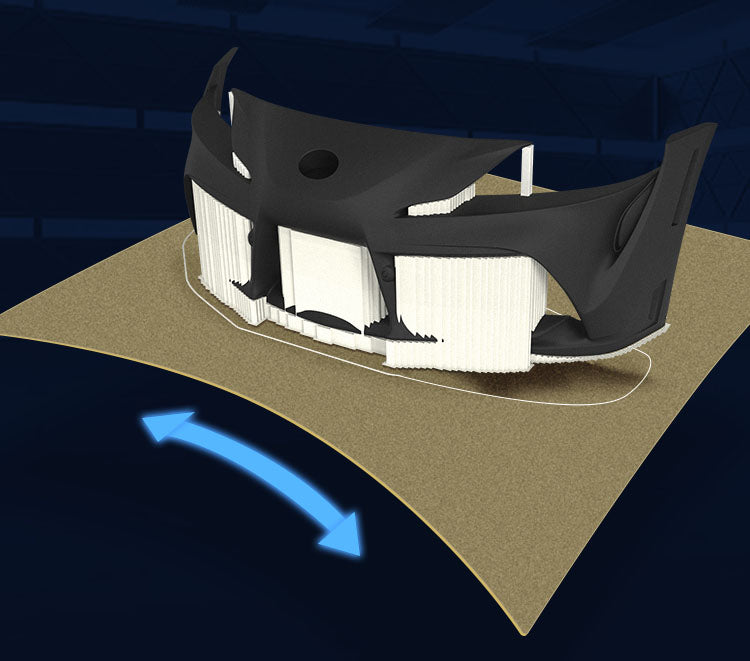

The PEI print surface with high temperature resistance ensures strong adhesion whilst printing, and is suitable for various consumables.

Once completed 3D prints can be removed with ease.

The heated bed heats to a Maximum of 110 °C

The print bed surface heats evenly to 60°C in just 75 seconds.

The fully enclosed chamber controls warping of prints, improved dimensional accuracy and significantly increased the strength of 3D printed parts.

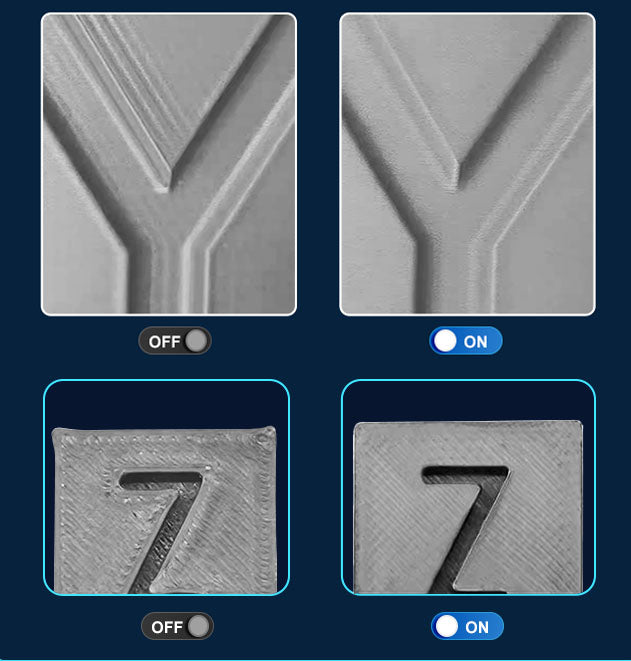

Input shaping technology improves print quality and accuracy.

Flow control allows precise management of the amount of filament being extruded, reducing errors like under/over-extrusion.

This leads to smoother prints with sharper details.

The MD-1000D enables you to combine hard and soft areas in a single part.

Tuned to print engineering-grade materials like their glass and carbon fiber reinforced Nylon, PET, and ABSand ASA variants but of course also prints PLA, PETG, or TPU with ease.

Soluble Supports

MINGDA has developed water soluble and easy break away supports ensuring clean printed parts on complex geometries.

General Use

ABS-HF ASA PETG-HF PLA ASA-Aero

Production End-use

PET-GF PET-CF PA12-CF HtPA-GF HtPA-CF ABS-CF20 HtPA-GF25 HtPA-CF25

Flexible Filaments

TPU95A-HF TPU-75D

Support Filaments

PVA S-Multi S-HTPA