Your Cart is Empty

Creality has erased the distinction between consumer-grade and professional printers with their Flagship K Series AI assisted Klipper controlled 3D printers. Sleek design, top-tier specifications,a tri-metal nozzle suitable for carbon composites at an affordable price establish the K1C as the stand out contender in its class.

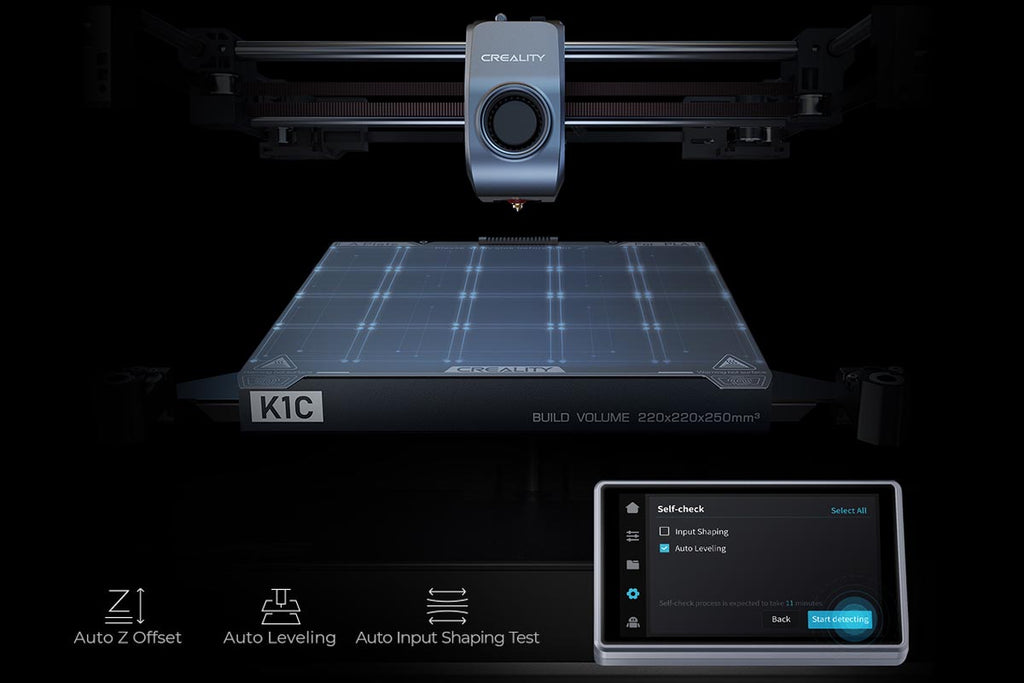

The K1C has a 220x220x250mm build volume.

Great for prototyping or design and printing in functional parts.

The fully enclosed build chamberassists in regulating air flow and retaining heat. This significantly reduces warping and increased part strength when printing in engineering materials.

A light weight rigid die-cast aluminum alloy core XY gantry ensures excellent print quality of 3d printed parts at high speed.

12x Faster than standard printers.

Reaches a print speed of 600mm/s in 0.03 secondsat 20000mm/s²acceleration.

Travel speeds are even higher up to 800mm/s.

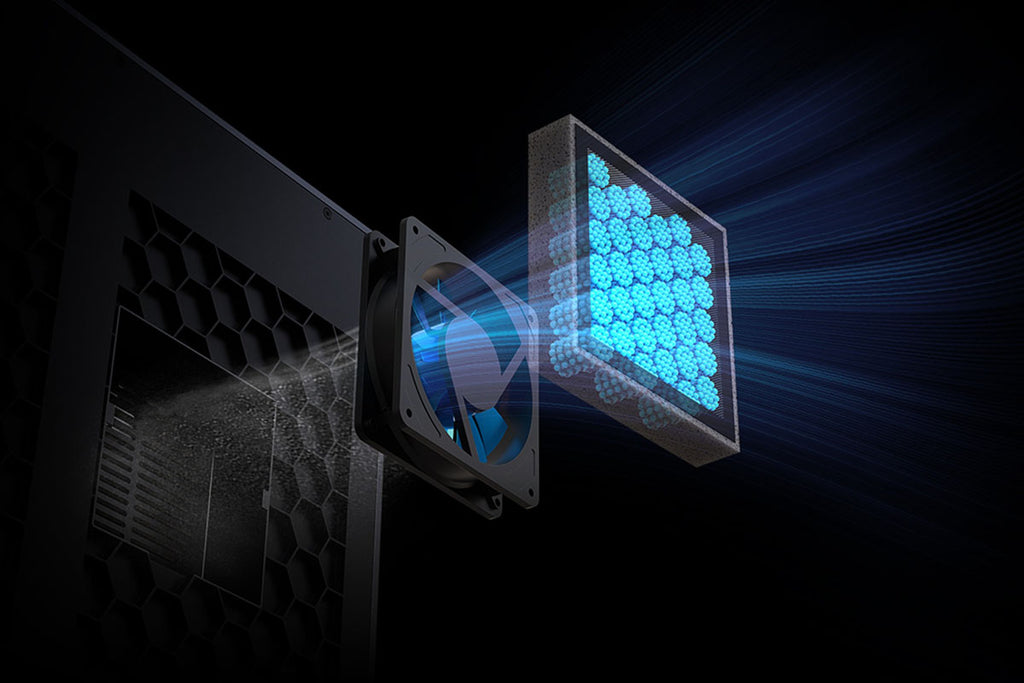

Ideal for the classroom- An Active Carbon Filter purifies air extracted from the printer reducing airborne particulates and compounds arising from printing molten filaments.

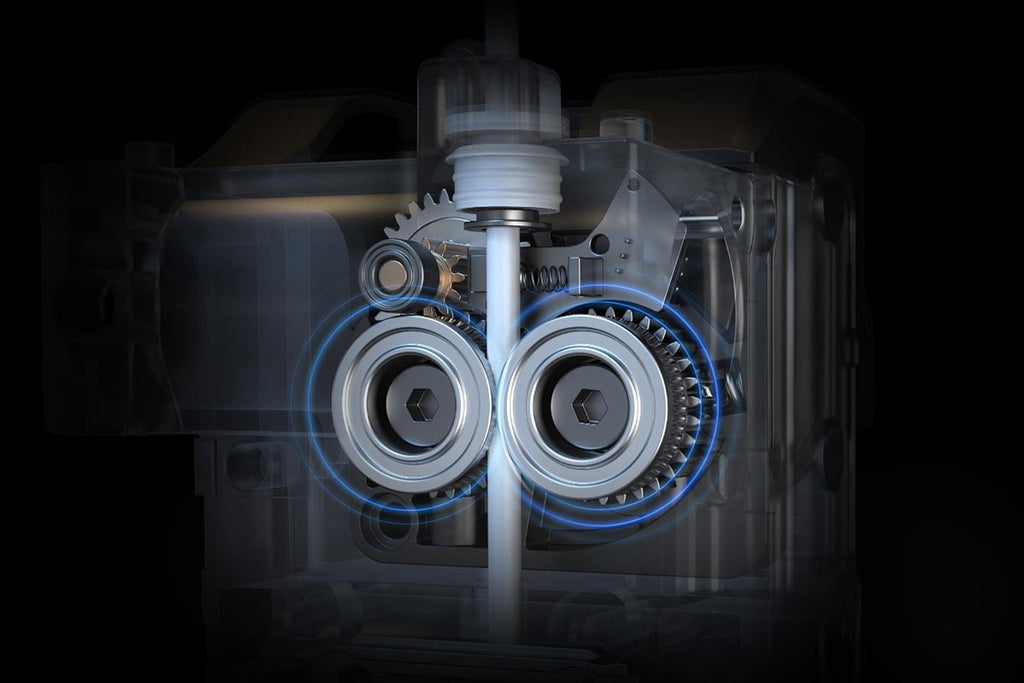

The Creality K1C is as capable as a professional 3D printer featuring an all-metal extruder kit, boasting 1000h clog-free extrusion. Enhanced by a bolster spring and a ball plunger, the extruder gives a tight grip on the filament that won’t slacken off.

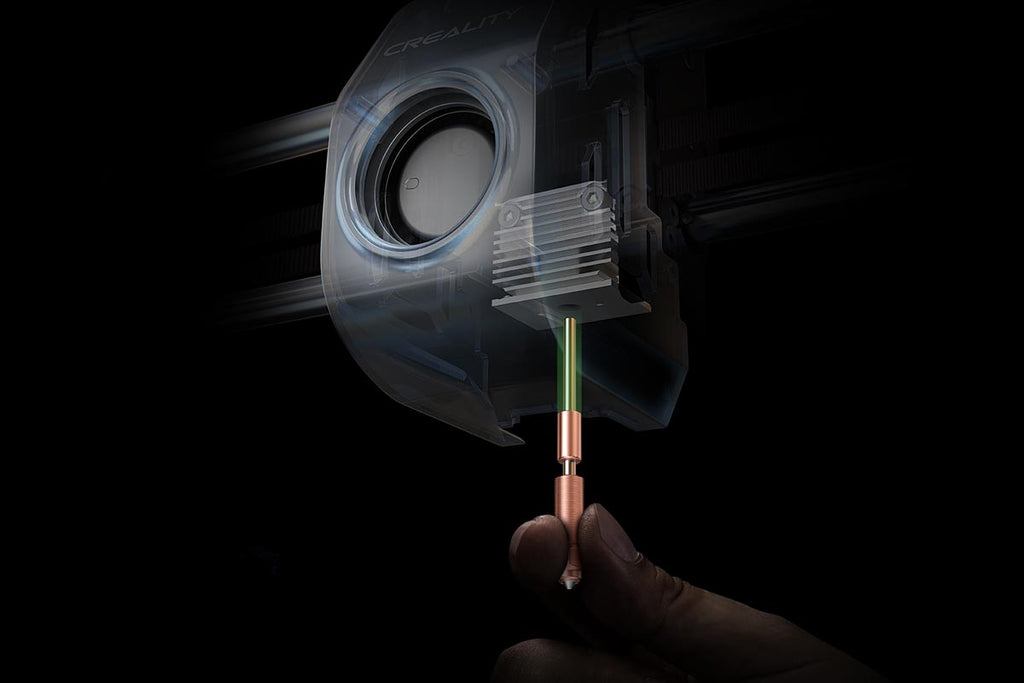

The “Unicorn” nozzle integrated with heat break blocks heat creep and can be swapped easily with one hand.

The nozzle is tipped with hardened steel. So, it can handle carbon fiber filled filaments such as PLA-CF and PETG-CF,

The all metal extruder is made of hard wearing metal to withstand wear from tough composite filaments such as carbon fiber composites. It is also capable of griping soft flexible materials such as TPU.

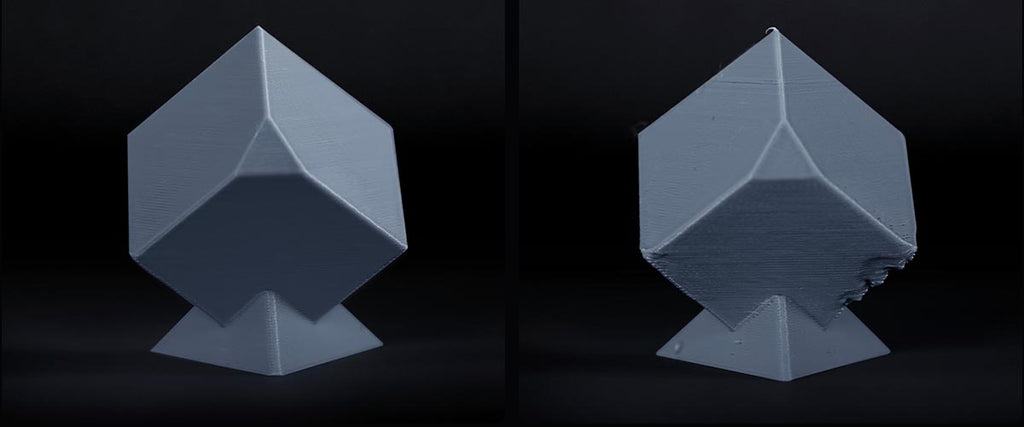

A high flow fan symmetrically blows air over the extruded material

ensuring an clean and layer adheasion and improved overhang quality

A large chamber fan circulated air within the build chamber ensuring layer adhesion and consistent print quality.

The model hardens before any stringing and warping could happen. It allows support-free bridges and overhangs.

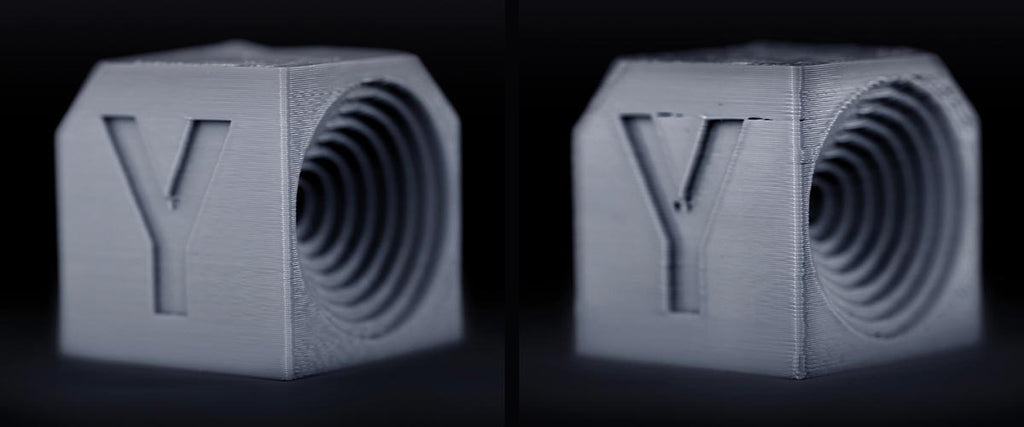

The Motion Advance options instructs Klipper to alter the pressure advance of filament flowing as the printer accelerated and decelerates.

This reduces ooze during non-extrude moves and provides consistent filament flow during extrusion-which reduces blobbing during cornering providing sharper detailand better surface quality.

No more frustrating paper test. To let more users enjoy the power of artificial intelligence, K1C comes standard with an AI camera that can watch over the printing for you and will actively alert you if an error occurs. It is also great for real-time AI monitoring and time-lapse filming

The integrated AI camera monitors the printing process and promptly notifies you of any errors. It will alert you when an error occurs. It also supports real-time monitoring and creates time-lapses for sharing.

Spaghetti Detection - Foreign Object Detection - Remote Monitoring - Time-lapse Video