Your Cart is Empty

We gladly accept school purchase orders!

$9,749.00 ex gst

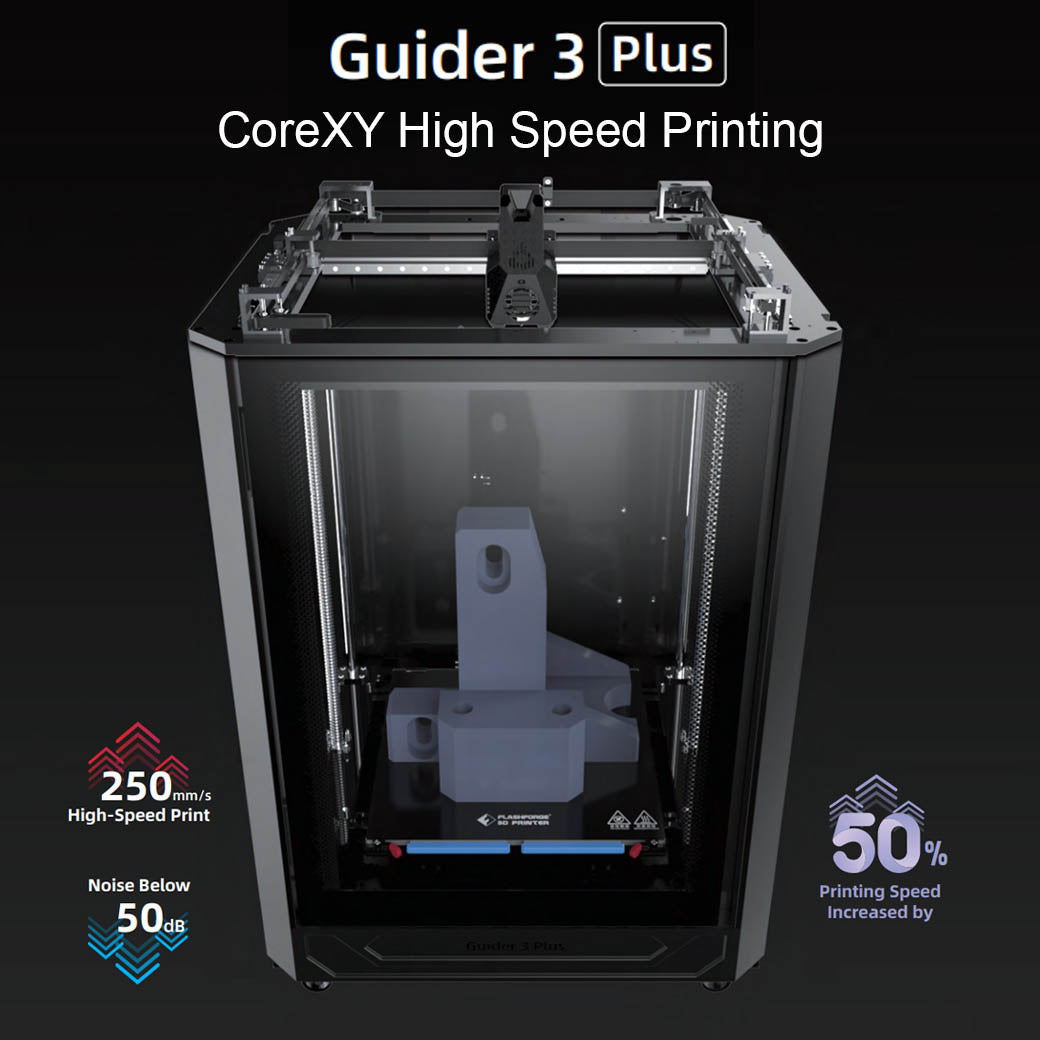

Guider 3 Plus is a professional-grade 3D printer, featuring high-speed printing, high model quality output, quiet and smooth operation. With a 350x350x600mm build volume, equipped with a full range of multi-platform intelligent management system for small business, studio, universities and laboratories, Guider 3 Plus assists engineers and designers in rapid prototyping. Guider 3 Plus can print in a large variety of engineering materials and supports carbon fiber composites printing and the consumption cost of carbon fiber material is overwhelmingly lower than the cost using other 3D printers in the market.

Guider 3 Plus is a professional-grade 3D printer, featuring high-speed printing, high model quality output, quiet and smooth operation.

Equipped with a full range of multi platform intelligent management system for small business, studio, universities and laboratories, Guider 3 Plus assists engineers and designers in rapid prototyping.

The coreXY gantry mechanism ensures stable and reliable printing at a larger build volumes with a higher surface quality and dimensional accuracy than conventional systems.

The X-axis and Y-axis adopt high-precision linear guide rails to improve the smoothness of movement.

Higher print speeds at lower noise are achievable with reliable printing speeds of up to at 250mm/s.

Various nozzles sizes and types can be easily swapped out between prints depending on the requirements of your next 3d print job.

Use larger nozzles for faster print times or high-strength nozzles for use composite materials including glass fiber and carbon fiber reinforced composite filaments.

Open Material System- Compatible with Third-party Filaments. Software includes material configuration presets for third-party materials.

Multi-diameter nozzle options: 0.3/0.4/0.6/0.8mm

Compatible printg material include-

PLA/ ABS/ HIPS/ PC/TPU /TPE /PETG /ASA /PP / Nylon / Glass fiber reinforced/ Carbon fiber reinforced/ Metal filled filament

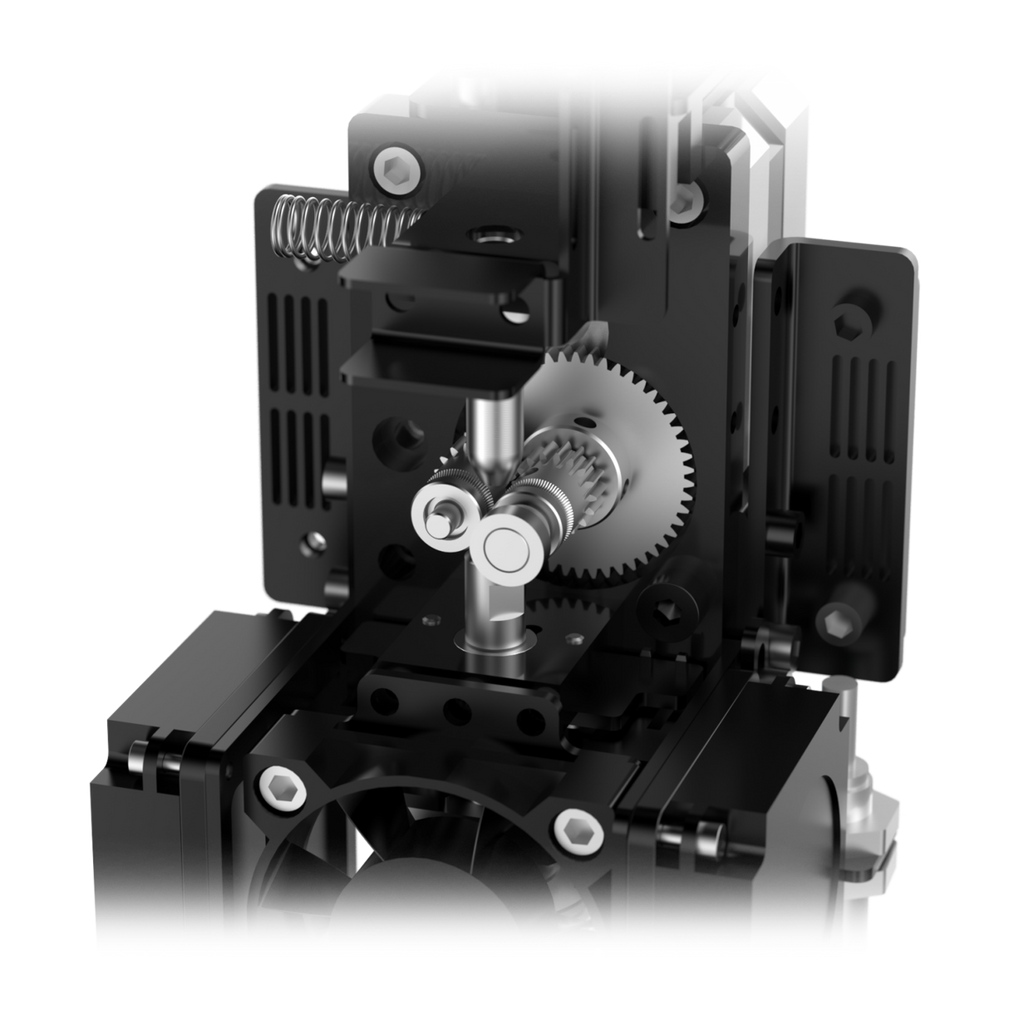

The dual-gear extrusion increases the filament feeding force by 150%. This reduces the change of filament slipping causing under extrusion. It improves the reliability of high speed printing and reduces the occurrence of nozzle clogging and print failures.

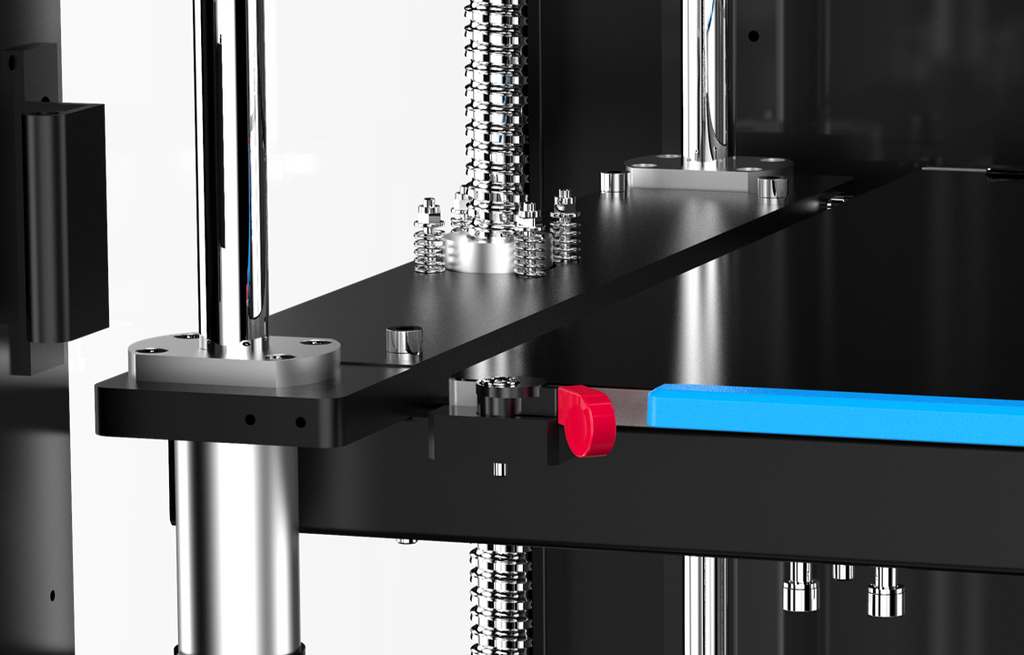

The Guider 3 Plus improves the load bearing capacity of the platform by incorporating 16mm-diameter optical axis and 16mm TBI ball screws. This reduces vibration and ensures the stability of printing large and heavy models.

In case of a power failure, the z axis will position will be saved and the printing progress may continue after power is resumed.

350 x 350 x 600mm build size

The build volume of 350*350*600mm can meet the needs of production and large-size rapid prototype development. Guider 3 Plus has the characteristics of high-speed printing, high surface quality and long-term stable operation.

The flexible build plate can be bent, making it easier to remove the

printed model and also reducing the potential damage to the model.

Third-generation platform design, no spring nut, no adjustment required.

The solid build and advanced motion system of the Guider 3 Plus ensures high quaity 3d printed parts achieving smooth and glossy model surface, with better presentation of delicate structures.

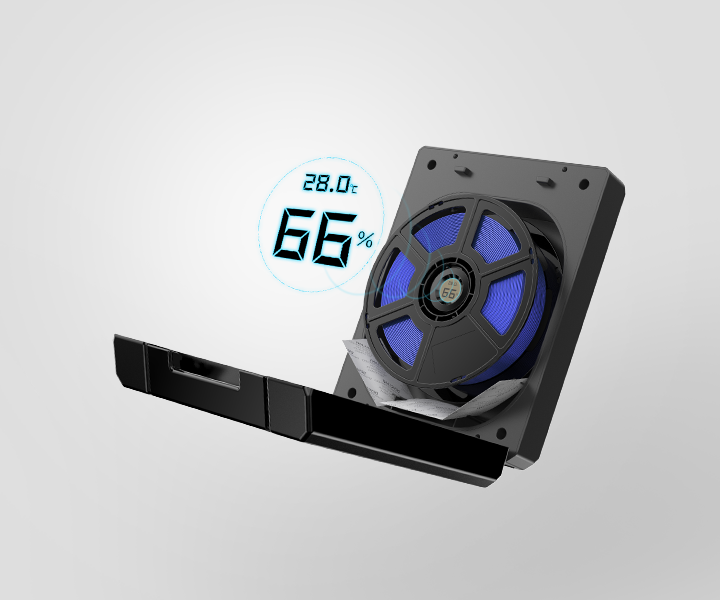

Hygrometer equipped, the humidity can be viewed, making it easy for users to accurately manage the filament environment.

Under general environment, the humidity can be kept below 20% within 5 days by placing 3 packs of desiccant in the filament chamber.

The Guider 3 Plus is designed with sealed filament chambers to prevent filaments from absorbing moisture and affecting the print quality, and to ensure stable properties of the filament.

Silica gel desiccant is stored inside the dual sealed filament chambers effectively ensuring that filaments are in a sealed and dry environment both during the printing process and in the idle state.

7-inch Touch Screen: Sensitive touch screen, online firmware upgrade, on-screen review of the time-lapse video shot during printing.

1080P Remote Video Monitoring: Long-distance dynamic video viewing via FlashPrint 5 Software, contributing to efficiently management of time-consuming large-size model printing.

Auto Power-off: The equipment can be set to be automatically shut down, and the equipment will be powered off after finishing printing, so as to guarantee the safety after night operation is completed and save energy and power.

Power Loss Recovery: There is no need for concern over the unstable circuit as our printer can resume printing after the power is restored.