Your Cart is Empty

We gladly accept school purchase orders!

$12,269.00 ex gst $13,360.00 You Save 8% ($1,091.00 ex gst)

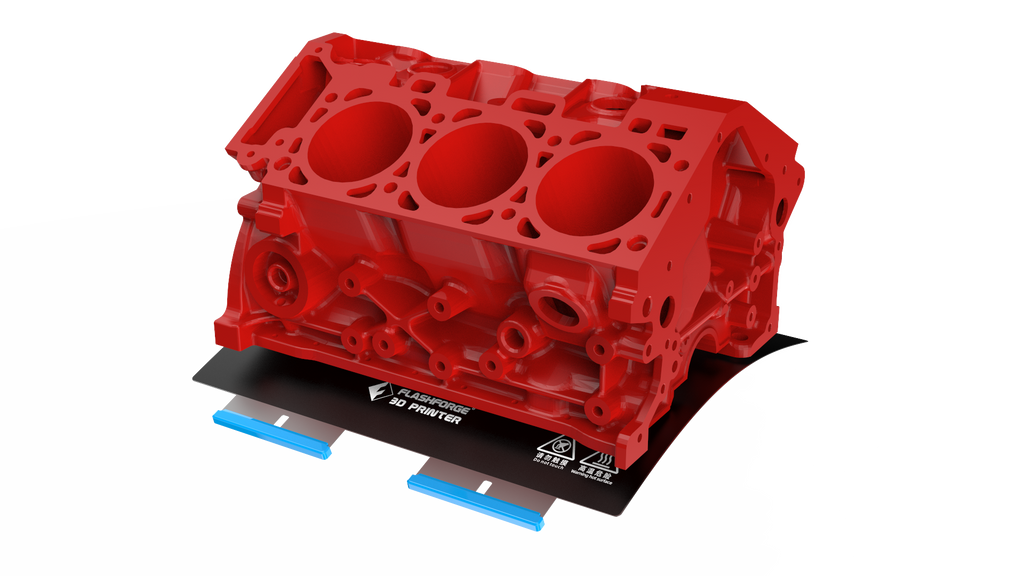

The Flashforge Creator 4 is a high-performance dual extruder 3d printer with a heated build chamber capable of printing in engineering materials for commercial production.

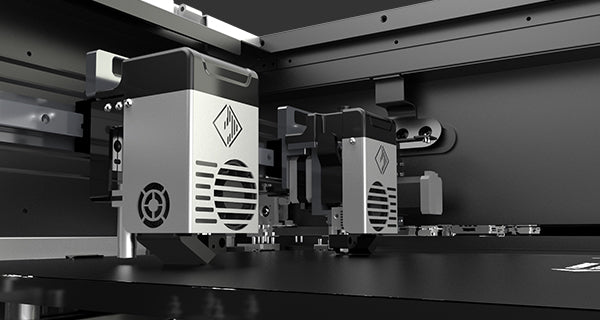

This version comes with a pair of Extruder-HT (for engineering materials) and a pair of Extruder-HS (for carbon fiber composite materials) extruders.

The Creator 4 is a large format high-performance 3D printer optimised for commercial applications. The temperature controlled build chamber controls warping and improves strength of producing 3d printer parts in engineering grade materials. Flashforge's Interchangeable Independent Dual Extrusion Systems with open filament support ensures the Creator 4 is capable of printing with high demanding materials from flexible, nylons, high strength and composites.

The thermal controlled build chamber can maintain a temperature of up to 65°C controlling warping of parts and improving dimensional accuracy and mechanical strength of 3d printed engineering materials.

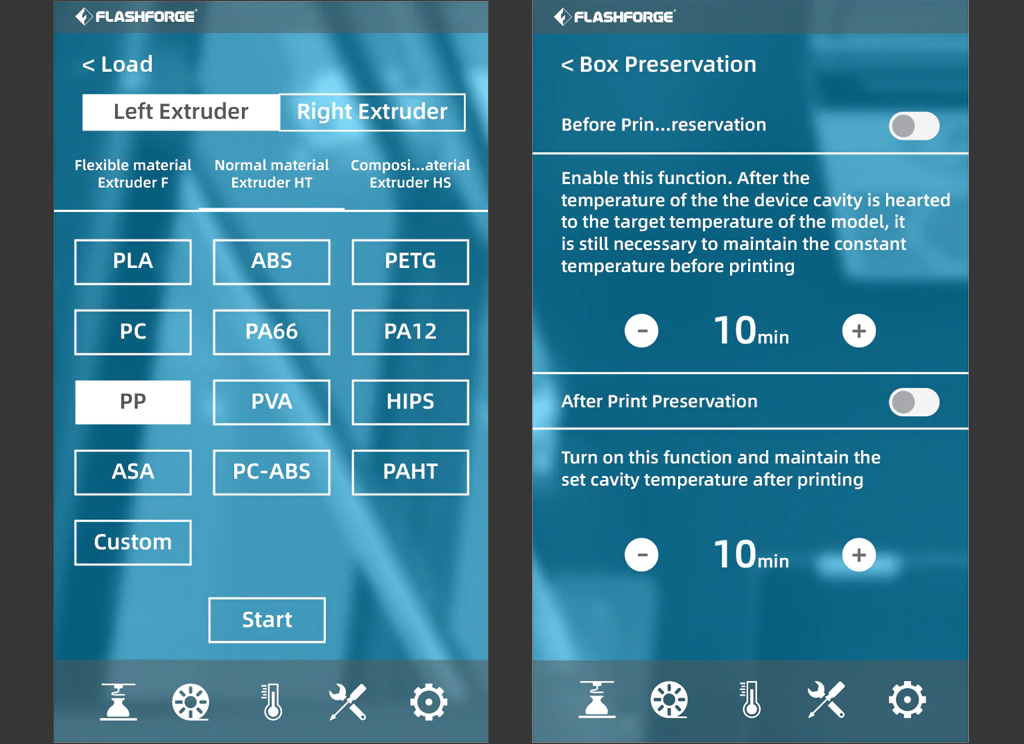

Extruder-F for flexible filament.

Extruder-HT for engineering filament.

Extruder-HS for carbon fiber composite.

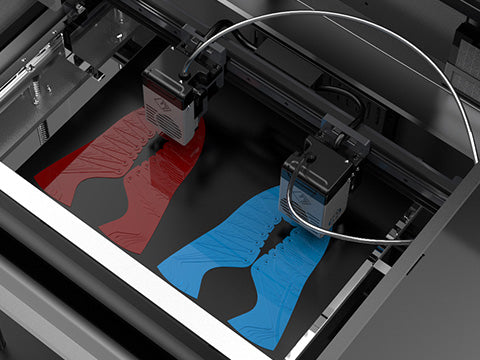

The two extruders can work independently enabling multiple items to be printed at once to double production output.

The Creator 4 supports high precision/ high speed print speeds of up to 200mm/s using oversize stepper motors and high quality linear rails.

Linear-rail leadscrew stepping along X and Y axes greatly improves motion stability, hence better printing precision.

S-type motion control system achieves

smoother start and stop, precise positioning of the nozzle, and

wonderful printing details.

CNC structure keeps machine stable and less shake when it's working

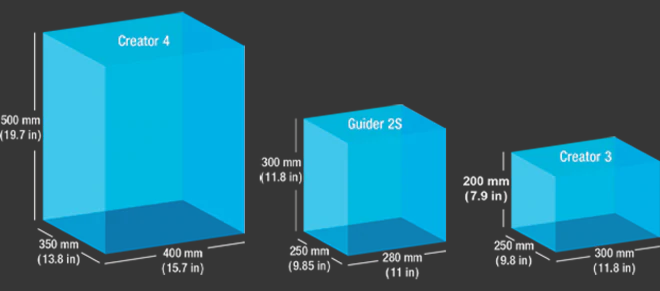

The Creator 4 is capable of printing 400 x 350 x 500mm

The build surface is automatically calibrated and locked into place whilst printing.

The intuitive touch screen of the Creator 4 enables the printer build chamber, bed temperature and nozzle temperature to be automatically prepared prior to printing. After a print job

is completed, the intelligent system then adjusts

the cooling temperatures throughout the system

in prepare for the next print job.