Q: What is the MakerBot RapidRinse™ material?

A: RapidRinse is a proprietary water soluble support material for ABS developed by Stratasys and MakerBot.

Q: Which MakerBot® 3D printers can print ABS-R and RapidRinse?

A: RapidRinse can be printed on the MakerBot METHOD X® and METHOD X Carbon Fiber Edition 3D printers.

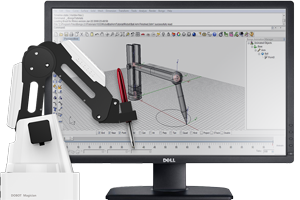

Q: Which extruder can print the ABS-R material?

A: The 1XA extruder is used to print the ABS-R material.

Q:Which extruder can print the RapidRinse material?

A: The 2XA extruder is used to print the RapidRinse material.

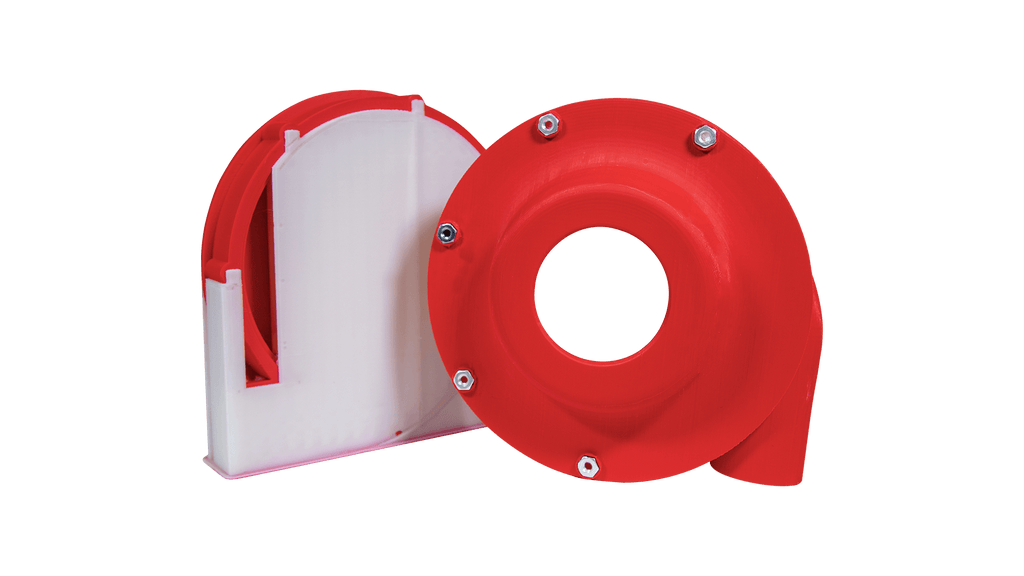

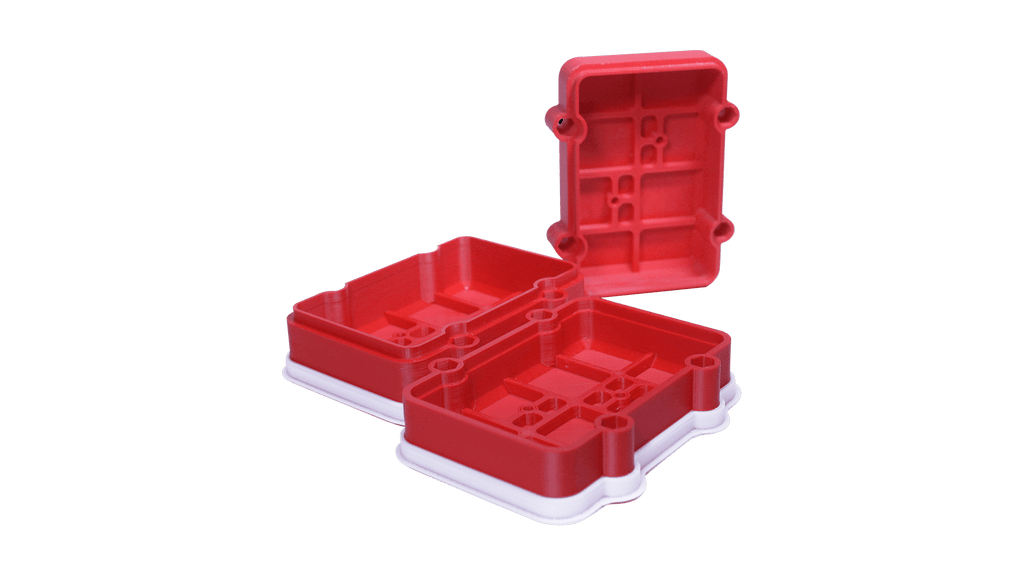

Q: Can I use ABS with RapidRinse?

A: No, the ABS-R material is specially designed to perform with the

RapidRinse material. MakerBot’s other model materials, including ABS,

will not adhere well with the RapidRinse material.

Q: Can I use RapidRinse with other model materials?

A: No, the ABS-R material is specially designed to perform with the

RapidRinse material. MakerBot’s other model materials will not perform

well with the RapidRinse material.

Q: Can I use ABS-R with SR-30™?

A: Yes, ABS-R will work with SR-30.

Q: What is required to dissolve RapidRinse supports?

A: Water is the only requirement to dissolve the RapidRinse supports.

Heat and agitation can accelerate the dissolution process.

Q: Recommended Support Removal Equipment

A: In addition to a tank with water, MakerBot recommends the following additional equipment for any support removal solution:

-Safety Gloves

- Waterproof and chemical resistant.

- Splash Resistant Safety Goggles

- Stainless Steel Tongs

- To remove large parts from the solution

- Stainless Steel Strainer

- To remove small parts if not using a small parts basket

Q: How should I dispose of the used solution?

A: A waste water profile is available for RapidRinse. Please reach out to customer support to

receive a copy. Check your local, state, and/or international

regulatory statutes for what is acceptable for disposal. MakerBot

recommends that disposal procedures be verified by the proper

authorities in your region. MakerBot cannot anticipate local, state, or

international regulatory statutes. MakerBot cannot be held liable if the

solution is not handled and disposed of properly. You may need to

document how you dispose of the used solution.

Q: Why does my build surface get damaged faster when printing with ABS-R?

A: The ABS-R material has improved adhesion to the build surface, which

may increase the wear and tear on the build surface. If you experience

excessive build surface wear, it is recommended that you replace the

surface. Spare build surfaces can be purchased here.

Q: How can I keep my filament dry?

A: It is critical to keep the filament as dry as possible. If the

filament absorbs moisture, this can result in poor print quality, such

as material oozing from the nozzle and stringiness in the print. We

recommend always keeping desiccant with your spools, whether stored in a

bag or in the machine. The bag must remain sealed and undamaged in

order to preserve the desiccant. There is desiccant in the spool hub on

the material spool, so be sure to always keep the spool and hub cap

together. Best practice is to always leave your spools in a sealed bag

or the machine with desiccant. Additionally, we recommend not opening

the sealed bag until the filament is ready to be used. If not using the

filament for a long time, we recommend removing it from the machine

drawer bay and storing it in a sealed bag with desiccant.

Q: What should I do if my filament is wet?

A: If your filament does absorb moisture from the air, the filament drying

feature on the machine can be used to dry it out. We recommend placing

the filament in a sealed bag with desiccant while running the drying

procedure on the machine.

Q: Which FW is required for printing RapidRinse and ABS-R?

A: Firmware 1.11 or later is required. If you receive a new machine, be

sure to update the firmware prior to completing the first run

experience. If your machine is connected to the internet, you should be

able to download the latest firmware directly to your machine. If your

machine is not connected to the internet, the please go to support.makerbot.com to download the latest firmware.

Q: When I cut my RapidRinse filament, it fractures and splinters. What can I do about this?

A: We recommend cutting your filament at a 45 degree angle to reduce the splintering.

Q: How can I slice prints with ABS-R and RapidRinse?

A: MakerBot CloudPrint™ software can be used to slice your prints.

Q:How does the dissolution speed of RapidRise compare to other soluble support materials on the market?

A: Our internal testing shows that RapidRinse filament dissolves

significantly faster than competing soluble support materials.