Your Cart is Empty

We gladly accept school purchase orders!

$3,359.00 ex gst

Pre Order- ETA late Jan

The Bambu Lab H2C 3D Printer with the Vortek System is a revolutionary new technology designed to achieve true multi-material and multi-colour 3D printing with virtually zero filament waste. It solves the problem of "purging"—the wasteful process of flushing out a nozzle with new plastic to avoid colour contamination—by fundamentally rethinking how a printer handles different materials.

The wait is over. The Bambu Lab H2C is here to rewrite the rules of 3D printing.

Forget everything you know about multi-colour printing. Forget the wasteful purge towers, the hours spent flushing filaments, and the risk of cross-contamination. The H2C introduces the revolutionary Vortek™ Hotend Change System, an industry-first technology that physically swaps the entire hotend in seconds.

Whether you are a professional engineer combining rigid Carbon Fibre Nylon with flexible TPU seals, or an artist creating vibrant 7-colour models, the H2C delivers the cleanest, fastest, and most efficient multi-material experience ever built.

The Bambu Lab H2C Vortek System is a revolutionary new technology designed to achieve true multi-material and multi-colour 3D printing with virtually zero filament waste. It solves the problem of "purging"—the wasteful process of flushing out a nozzle with new plastic to avoid colour contamination—by fundamentally rethinking how a printer handles different materials.

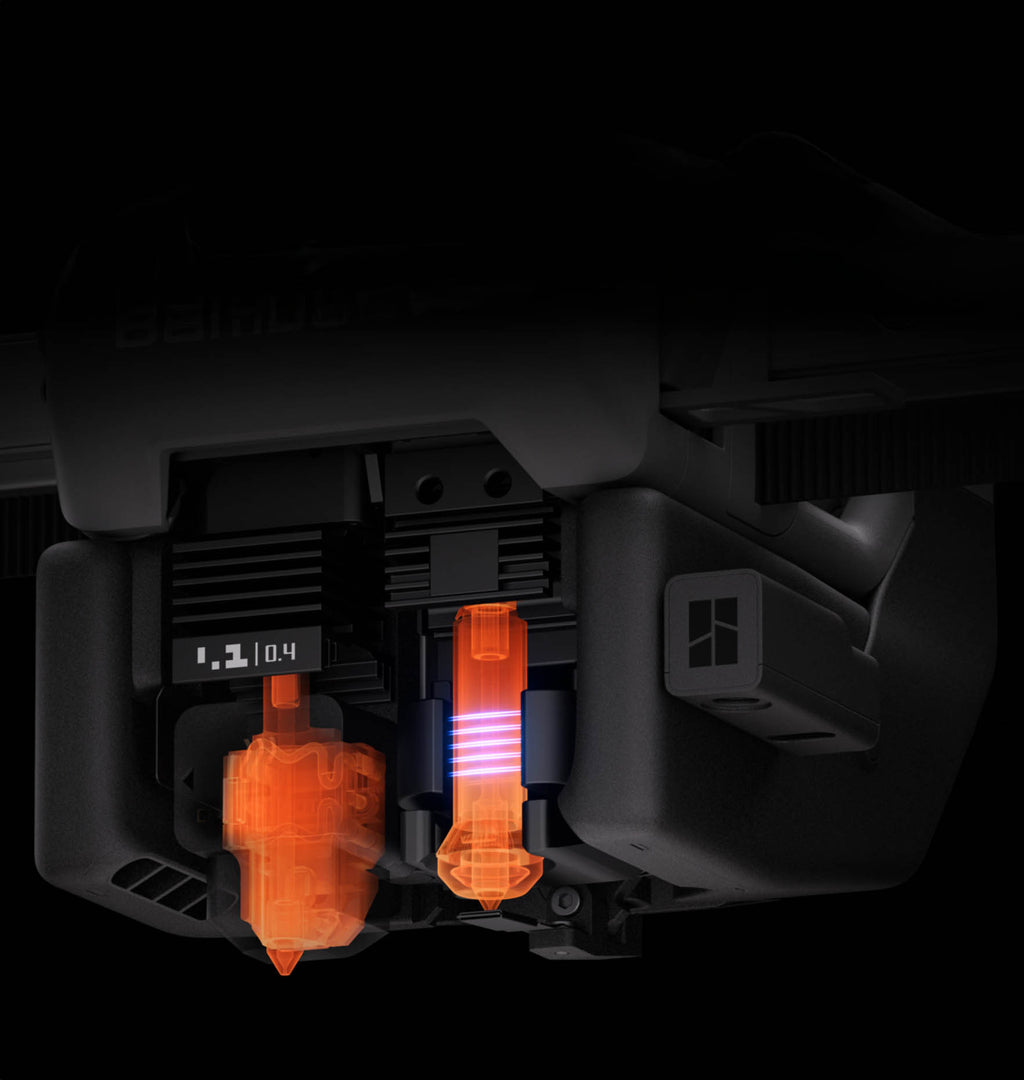

Instead of using a single nozzle that requires repeated cleaning, the Vortek system utilises multiple, dedicated hotend assemblies for each filament. When a material change is needed, the printer's toolhead automatically swaps the entire active hotend for a new one. This process is significantly faster and more material-efficient than traditional purging methods.

Traditional multi-colour printers waste time and plastic purging old filament from a single nozzle. The H2C eliminates this.

It houses up to 6 induction-heated hotends inside the toolhead. When it's time to change colour or material, the printer automatically swaps the entire hotend in seconds.

Time is money. The H2C features cutting-edge induction nozzle heating that brings the hotend to printing temperature in just 8 seconds. Combined with the rapid hotend swap, this slashes transition times and makes multi-material printing significantly faster than any competitor.

This is a serious production machine.

Seriously strong production materials.

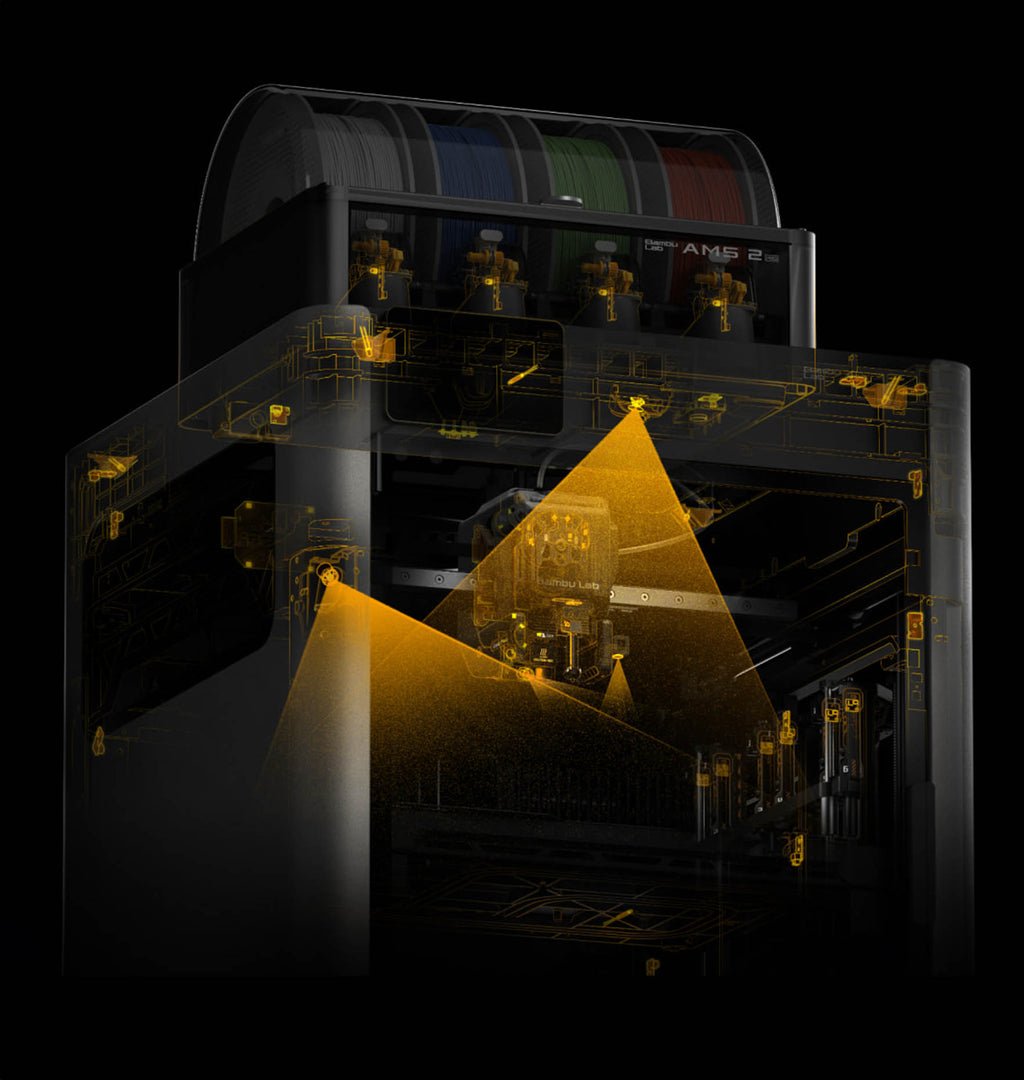

Full Filament Path AI: The H2C uses advanced AI sensors to monitor the filament from the spool to the nozzle, detecting tangles, clogs, or run-outs instantly.

Featuring 59 sensors and a quad-camera computer vision system, all controlled by our exclusive neural algorithm. This system provides real-time diagnostics during printing to identify any print anomalies. Let the printer handle troubleshooting, no expertise needed.

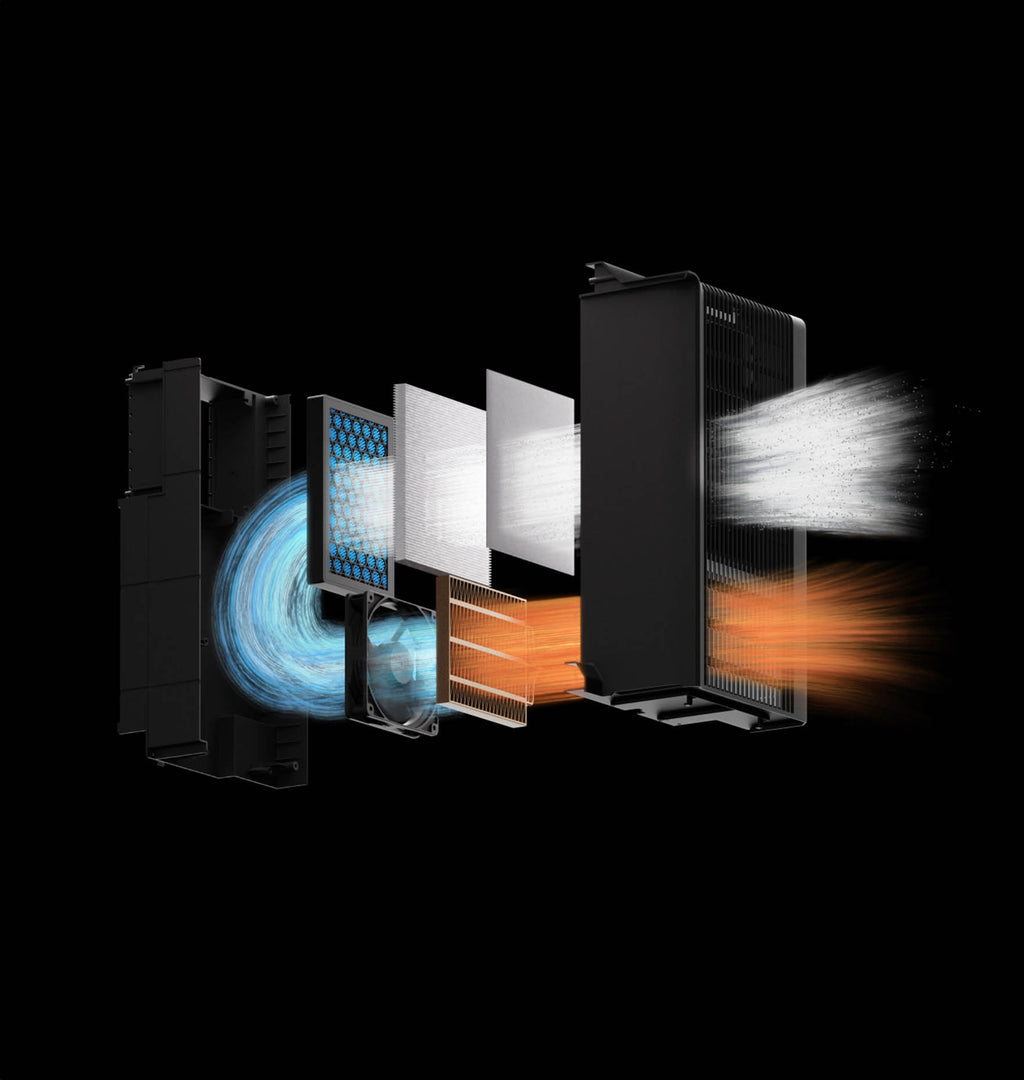

The H2C's three-step filtration system is crucial for printing with engineering filaments. This effective mix of a G3 pre-filter, an H12 HEPA filter, and a coconut shell activated carbon filter reduces odors and harmful particulates commonly emitted by engineering materials.

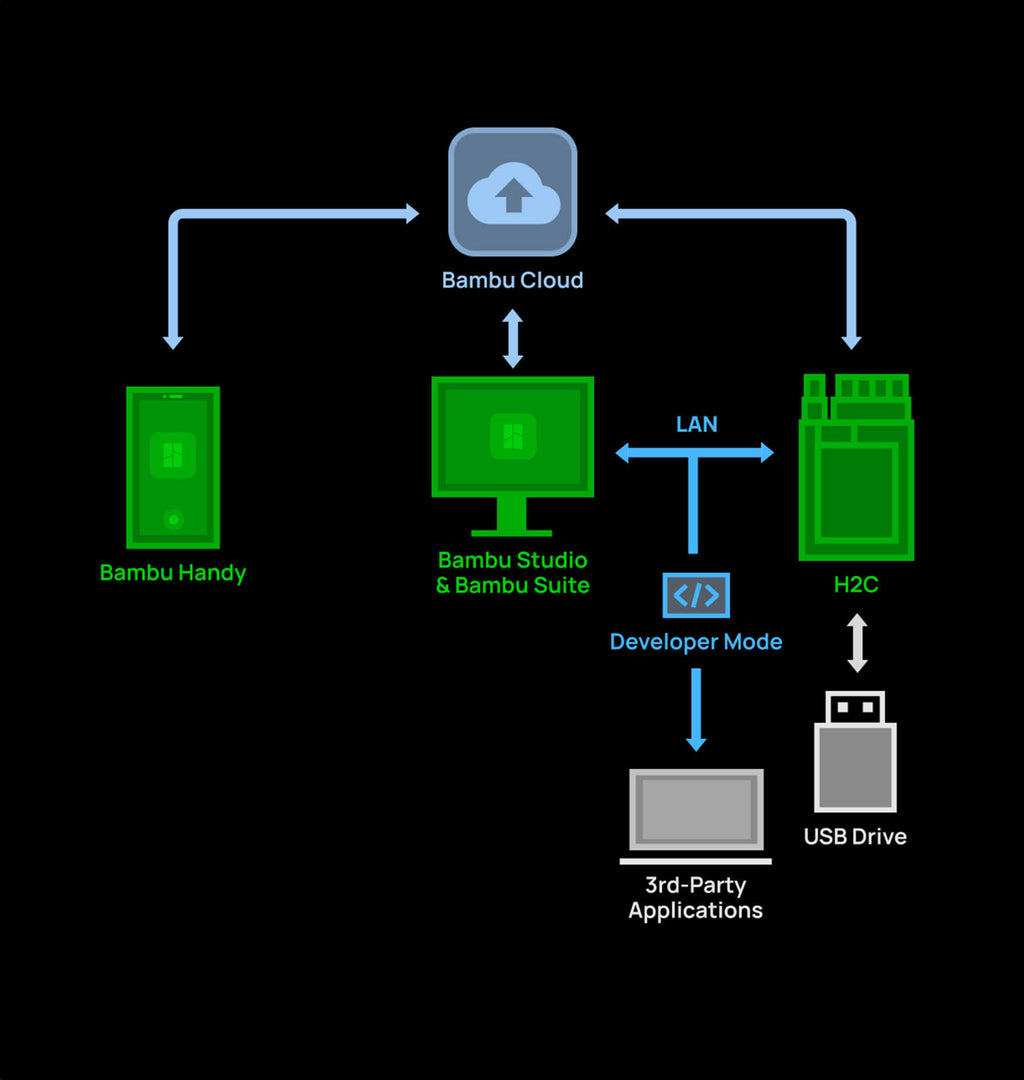

The H2C offers convenient cloud connectivity for remote control from any device. For security-sensitive applications, it also provides full offline functionality, ensuring complete physical isolation. Users can operate the printer, send files, and update firmware without an internet connection. For advanced users, Developer Mode enables MQTT port access for integrating third-party components and software.