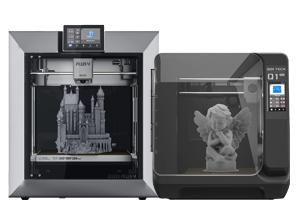

The wait is over. The Bambu Lab H2C is here to rewrite the rules of 3D printing.

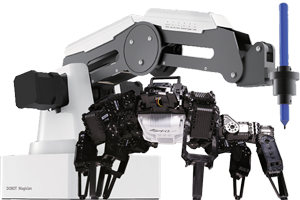

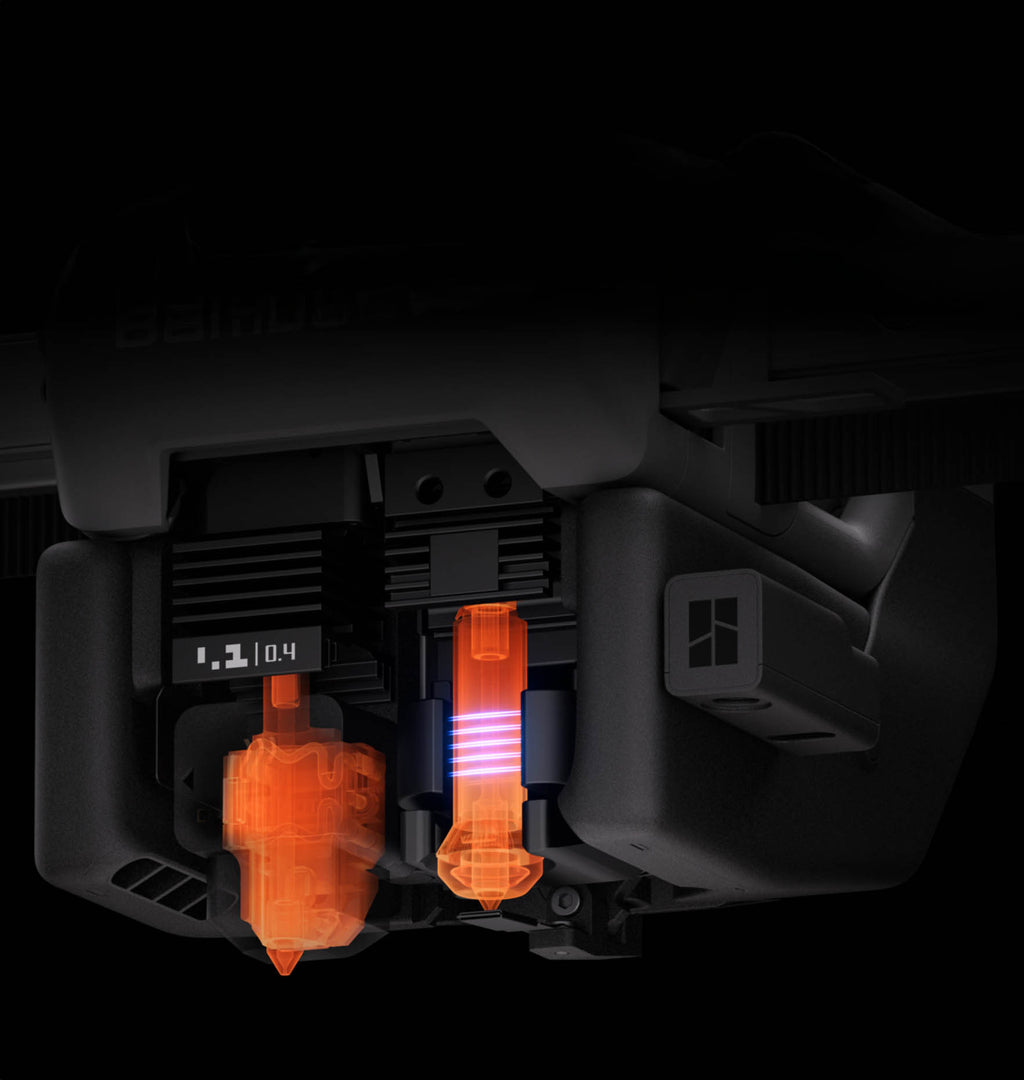

Forget everything you know about multi-colour printing. Forget the wasteful purge towers, the hours spent flushing filaments, and the risk of cross-contamination. The H2C introduces the revolutionary Vortek™ Hotend Change System, an industry-first technology that physically swaps the entire hotend in seconds.

Whether you are a professional engineer combining rigid Carbon Fibre Nylon with flexible TPU seals, or an artist creating vibrant 7-colour models, the H2C delivers the cleanest, fastest, and most efficient multi-material experience ever built.

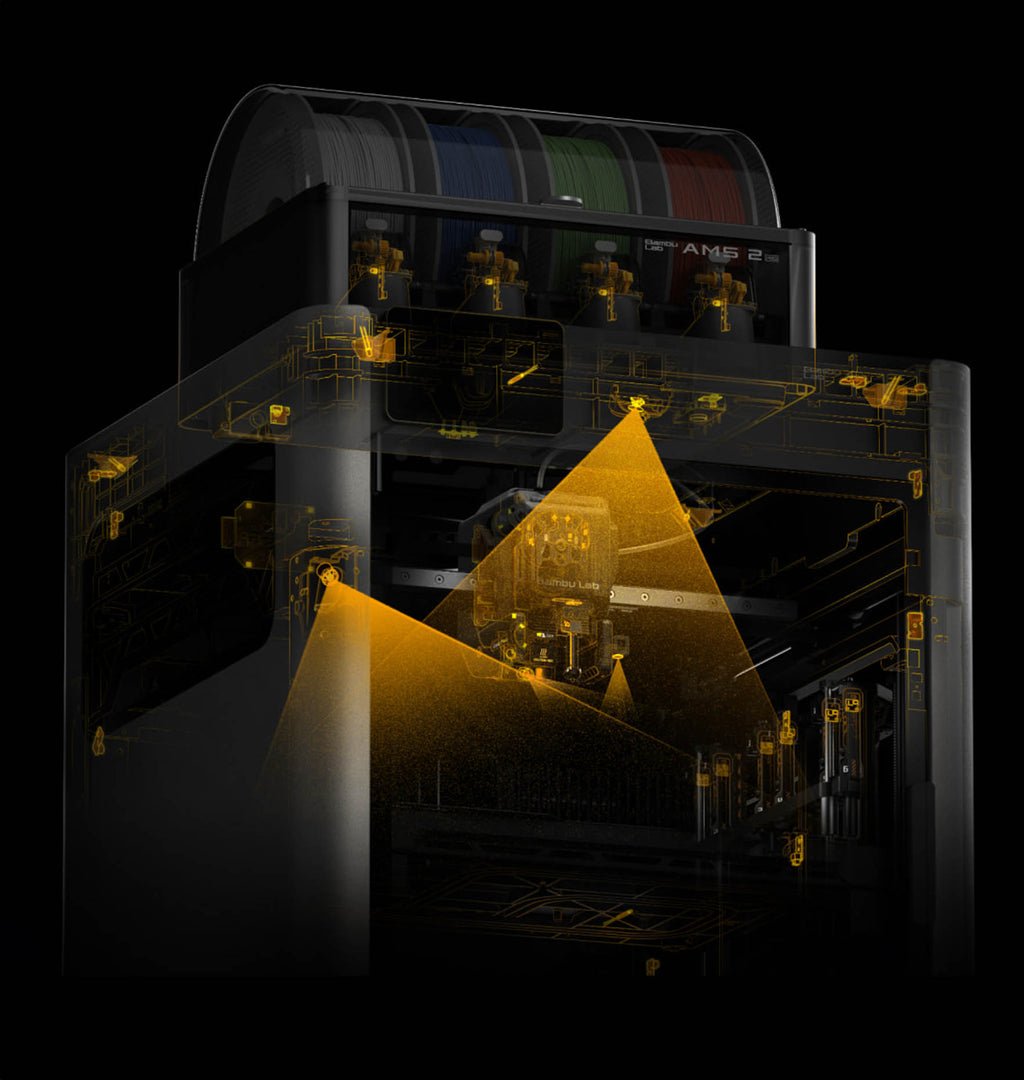

The Bambu Lab H2C Vortek System is a revolutionary new technology designed to achieve true multi-material and multi-colour 3D printing with virtually zero filament waste. It solves the problem of "purging"—the wasteful process of flushing out a nozzle with new plastic to avoid colour contamination—by fundamentally rethinking how a printer handles different materials.

Instead of using a single nozzle that requires repeated cleaning, the Vortek system utilises multiple, dedicated hotend assemblies for each filament. When a material change is needed, the printer's toolhead automatically swaps the entire active hotend for a new one. This process is significantly faster and more material-efficient than traditional purging methods.