Your Cart is Empty

We gladly accept school purchase orders!

$1,135.45 ex gst

NOW IN STOCK (finally)!!!!

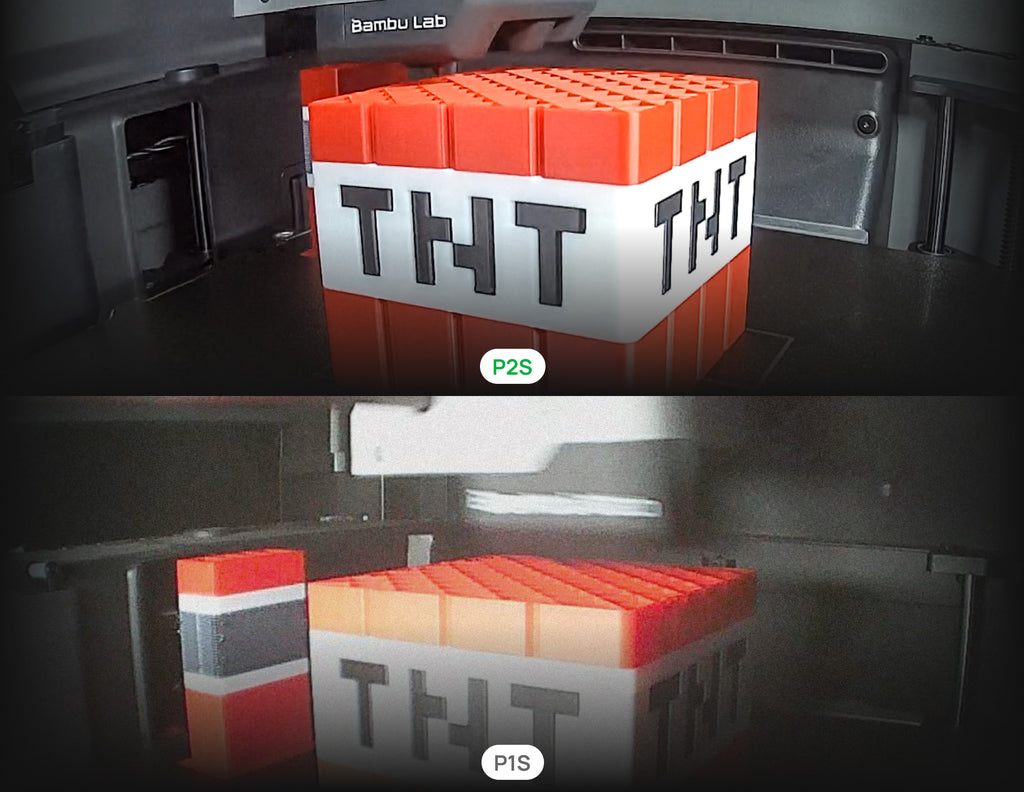

Meet the Bambu Lab P2S, the evolution of the legendary P1S and the new workhorse for Australian makers. It’s not just an upgrade; it’s a revolution in your workshop. Experience blistering 600mm/s print speeds without sacrificing an ounce of quality, thanks to its rock-solid CoreXY frame and advanced vibration compensation. Unlock breathtaking multi-colour prints with seamless AMS 2 Pro integration, and take full command through a brilliant full-colour touchscreen. With a hardened steel nozzle ready for advanced materials and an intelligent, fully enclosed chamber perfect for our variable climate, the P2S is engineered to turn your most ambitious ideas into stunning reality, right out of the box.

The P2S takes the "it just works" philosophy of the beloved P1S and elevates it with a suite of technologies trickled down from Bambu Lab's flagship X1 Carbon and H2D series printers. This isn't just a printer; it's a complete, finely-tuned ecosystem designed for meticulous reliability and boundless creativity. It embodies a "Function Over Form" philosophy, where every detail of its minimalist design conceals meticulous engineering aimed at delivering an unparalleled printing experience.

The P2S features an upgraded touchscreen and powerful processor, with a new second-generation UI.

With better graphics and step by step instructions- the entire user experience has been revolutionised, starting with the stunning new 5-inch full-colour touchscreen. This vibrant, responsive display replaces the P1S's basic dot-matrix screen, providing an intuitive and modern interface for controlling every aspect of your print. It's the command centre for a truly seamless workflow.

Monitor your prints from anywhere in crystal-clear detail with the upgraded "stage light" and 1080p high-framerate camera. Paired with the powerful Bambu Studio slicer on your computer and the Bambu Handy app on your phone, you have complete remote control—from slicing and sending jobs to checking progress and viewing stunning timelapse videos of your creations.

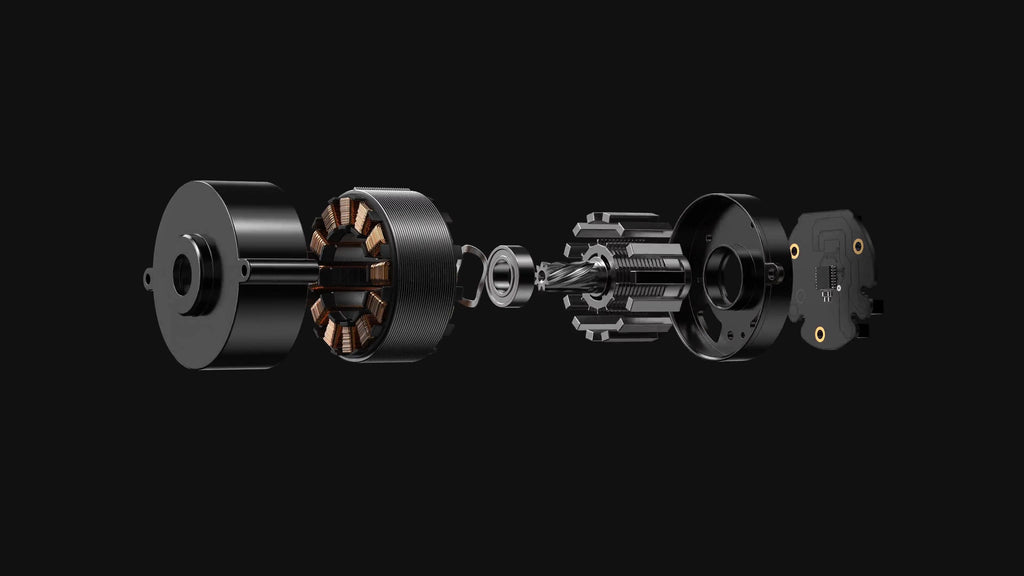

Featuring a 70% increase in extrusion force compared to the previous model, this product significantly enhances high-flowrate extrusion stability. The servo system utilizes a proprietary architecture to monitor resistance and position at a rate of 20 kHz, effectively identifying filament grinding and clogs in real-time.

The P2S employs a high-resolution, high-frequency eddy current sensor for flow dynamics calibration. Smart algorithms dynamically regulate flow rates for accurate, uniform extrusion on all surfaces.

Perfect Overhang No Matter the Filament or Temperature.

In contrast to conventional cooling systems that recirculate hot air, the P2S's Adaptive Airflow System pulls cool air from outside the chamber. This enhances cooling efficiency, enabling the printing of low-temperature filaments with the door shut, without concerns about overhang quality or nozzle clogs.

The P2S showcases a flap-controlled Adaptive Airflow System that effectively seals heat within the chamber preserving heat up to 50°Cwhile filtering the internal air through a high-performance carbon filter. This system actively regulates the internal environment which enables printing of demanding engineering filaments prone to warping, maintaining clean, safe air quality in your workspace.

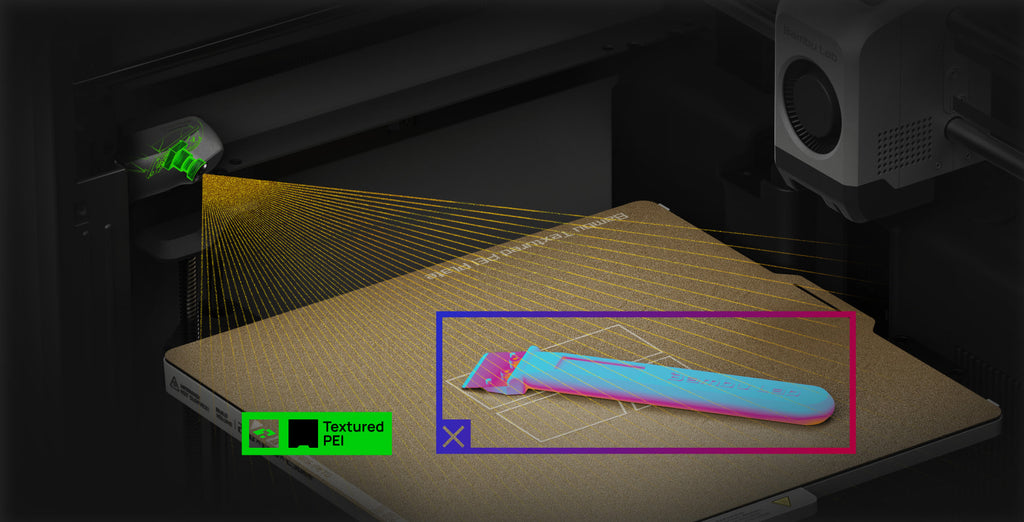

The P2S features cutting-edge AI computer vision to actively identify typical printing problems such as spaghetti and nozzle blobbing. It also validates print start settings for a secure and precise start to each job.

Start Check- collision avoidance

Spaghetti Detection-not so faster pasta

Nozzle Clumping- detects filament building up on nozzle

Purge Chute Jams- identifies a build up of filament purge blocking the exit chute

P2S has a quick-swap hotend design with a one-clip mechanism for easy nozzle changes.

The P2S is built to handle whatever you throw at it. The redesigned toolhead, inspired by the high-end H2D, features a powerful magnetic servo extruder that can exert approximately 70% more force than its predecessor. This ensures a consistent and powerful flow of filament, which is critical for maintaining quality at high speeds.

The P2S all-metal hotend reaches temperatures up to 300°C with a hardened steel nozzle, allowing printing of various materials. Explore ABS, ASA, carbon-fibre, and glass-fibre filaments not recommended for the P1S.

Unleash a world of vibrant creativity with the P2S's seamless integration with the Bambu Lab Automatic Material System (AMS). The P2S is fully compatible with both the original AMS and the new-generation AMS 2 Pro, offering a true plug-and-play multi-filament experience. But the AMS is far more than a tool for multi-colour printing. It's a productivity powerhouse that streamlines your entire workflow.

The P2S ecosystem is incredibly expandable. A single AMS 2 Pro unit allows for seamless 4-colour printing. For the ultimate creative freedom, you can connect up to four AMS units via the optional AMS Hub, unlocking the potential for 16-colour prints. To reach the maximum capability of 20 different colours and materials, this 16-colour setup can be combined with four additional single high-temperature HT AMS filament holders, allowing for breathtakingly complex jobs. While this process does generate purged filament waste as a trade-off for its capability, the creative freedom it provides is simply unmatched at this price point.