Your Cart is Empty

We gladly accept school purchase orders!

We gladly accept school purchase orders!

We gladly accept school purchase orders!

$149.00 ex gst

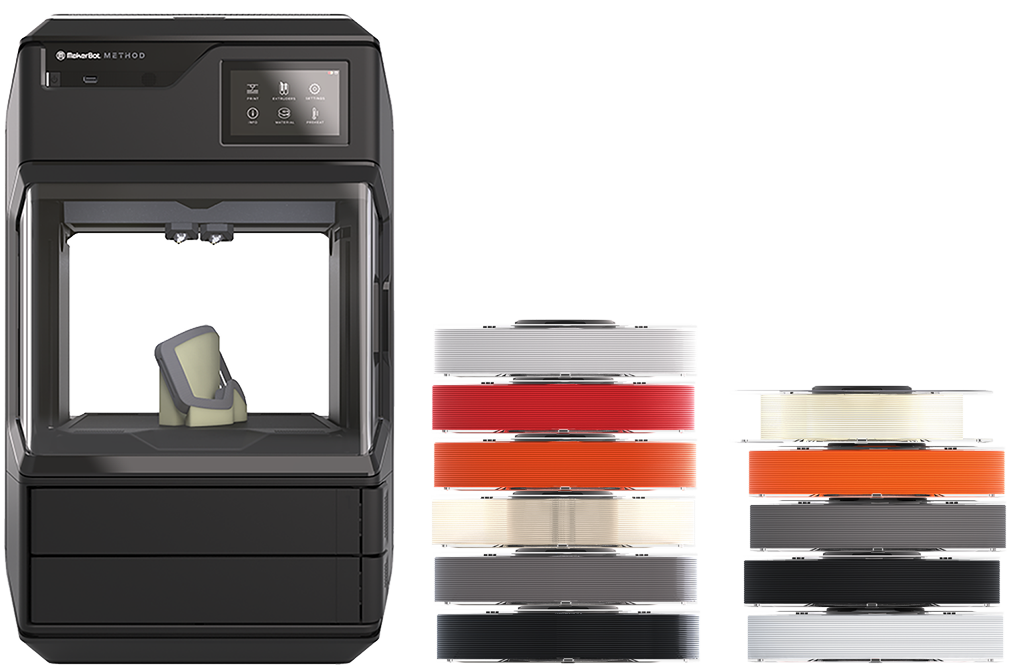

This is the material for the Method 3D printer from Makerbot Industries, it has been designed and tested to work perfectly with Makerbot's industrial grade printer. Shipped in a vacuum-sealed metalized polyester bag, quality is preserved right up until opening.

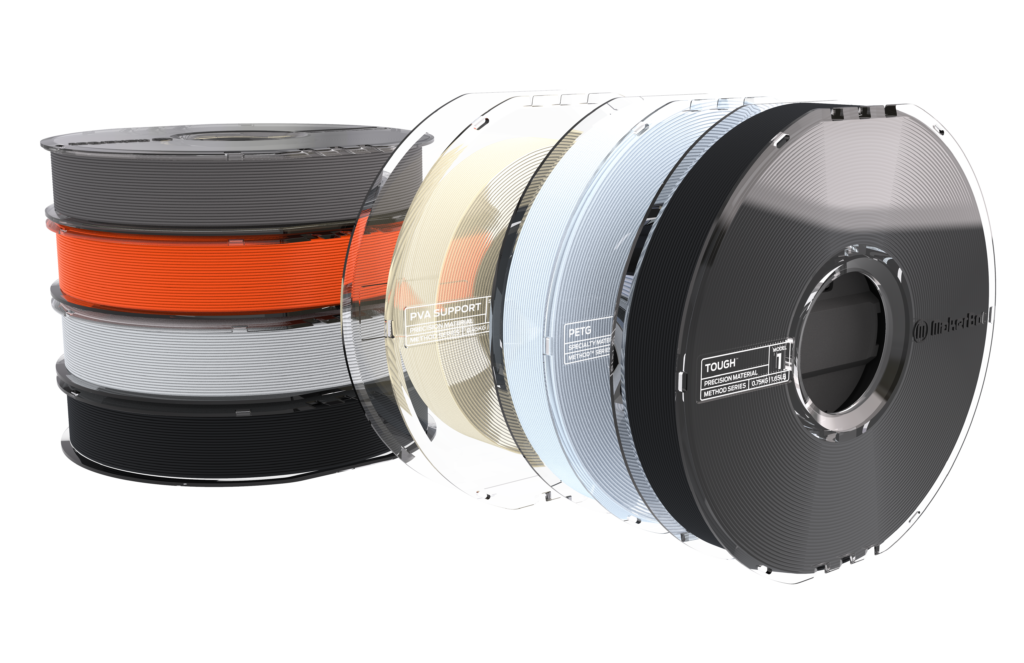

The Smart Spool contains all the information that the printer needs, including material type, color, and amount remaining via an RFID chip. This is communicated directly to MakerBot Print, while a built-in desiccant absorbs any moisture exposure during the material loading process, ensuring your material stays fresher longer.

Polylactic acid (PLA) is a biodegradable thermoplastic derived from renewable resources. Safe for the office, this material is non-toxic and easy-to-print with high reliability and dimensional accuracy. MakerBot precision PLA Material is optimized with the Makerbot Method printer in mind. Ideal for the early stages of concept modelling and form studies, PLA printed objects will generally have a glossier look and feel.

PRINTER COMPATIBILITY

MakerBot Method

MATERIAL TYPE

PLA Precision Model Material: Extensively-tested for the highest reliability and measurably accurate parts.

SPOOL TYPE

Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay.

SOFTWARE COMPATIBILITY

MakerBot Print

TEMPERATURES

Glass Transition Temperature: 60-65°C

Melting Temperature: 150-160°C

Extruder Temperature: 210°C

DIMENSIONS AND WEIGHT

Spool Diameter: 21.8 cm

Spool Width: 4.2 cm

Material Diameter: 1.75 mm

Shipping Weight: 1.1 kg

Net Weight: 0.75 kg

OPERATING ENVIRONMENT

Store MakerBot Method PLA Precision Material in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air and long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is ion the spool to absorb any moisture exposure during the material loading process.

We won't spam you (we hate spam!) We only send cool relevant info and exclusive offers...

Adhesion better than I envisaged.

Very helpful on phone and dispatched an delivered super quick.

Bought two AD5X , they are simply great

Love the product….and the customer service was absolutely awesome….see you again when I make another purchase through you…

I am so grateful to the staff at the store for helping me with the power supply that I needed for my printer. They were so helpful and sourced the original for me when I couldn't afford the one they had. Thanks mostly from my kids who now have an awesome, functional 3Dprinter.

The best printer (third) have ever had. Seamless prints with very user friendly soft ware. Would thoroughly recommend for anyone starting out in 3D printing. 👌