Your Cart is Empty

We gladly accept school purchase orders!

$3,469.00 ex gst

Product Highlights

Optional

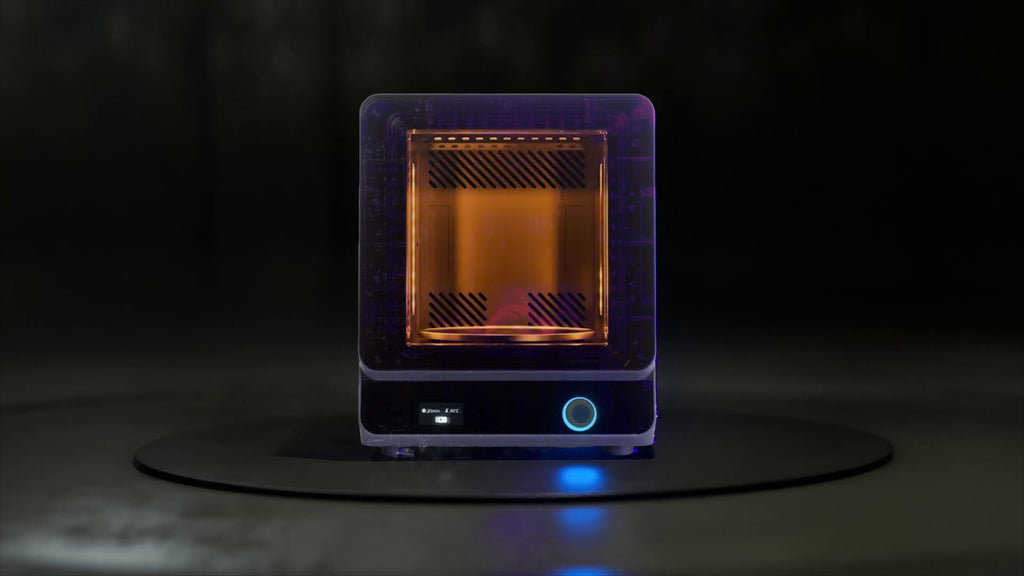

Welcome to a new era in SLA 3D printing. Producing high quality, highly detailed, engineering grade production parts with higher dimensional accuracy than injection molded parts has never been easier.

HeyGears UltraCraft Reflex Combois a complete end-to-end professional resin 3d printing solution designed to make resin 3D printing post-processing a worry free process. Powered by AI algorithms and an automated process you can achieve professional commercial grade results with ease.

HeyGears has produced an all-in-one production platform enabling users to actualise ideas faster and materialize them. Its advanced features and capabilities make this resin 3D printing solution innovative and efficient in streamlining the production process towards the final outcome.

The printer’s advanced features and intelligent AI algorithms assure smoother surfaces and stable performance, akin to injection molded-like final results.

Users can anticipate next-level surface quality and fine details for their prints.

The UltraCraft Reflex also showcases industrial-grade hardware, ensuring durability and reliability for every print. Additionally, the product’s SmartAI peeling force management significantly increases print success rates with consistent results.

With unmatch print results HeyGears’ self-developed TrueUV 385nm+ 3D printing resins provide users with the greatest performance for their final print results.

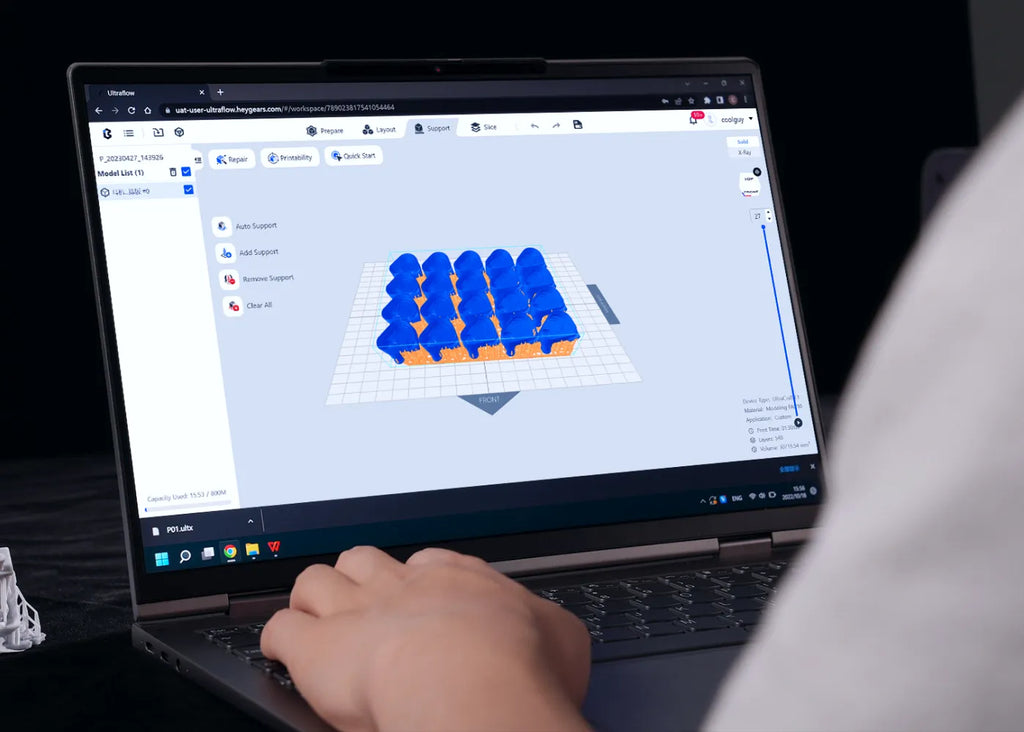

HeyGears Blueprint Software takes the hassle out of SLA printing.

The software provides a print strategy based on the mechanical and material properties and features required from a finished part. It then recommends which materials will be suit the needs of the user.

Each component of the Relfex Combo are linked via Wi-Fi. Blueprint automatically matches the optimum process and parameters for each print ensuring cycle to ensure perfect results.

With one click- It intelligently manages each step of the production process, from optimal martial selection, part orientation, print parameters, as well as washing and curing settings ensuring optimum results.

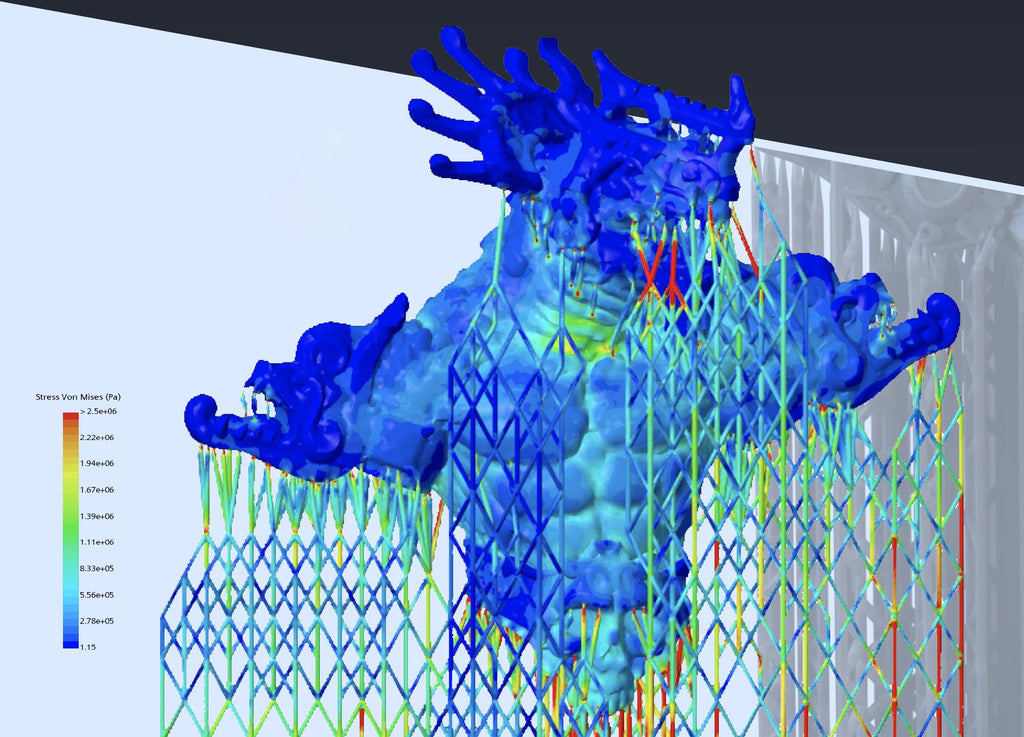

WIth inteligent algorithims- scafford supports are automatically generated and optimised based on the resin used and the peel forces.

Easy to Remove Scaffold Supports

Support structures are easy to remove, even on large complex models.

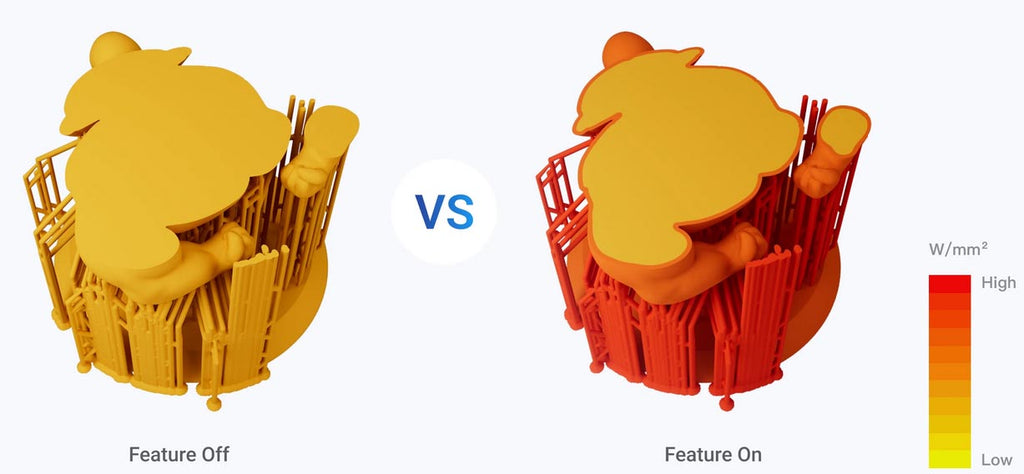

A game changer in MSLA resin print quality and accuracy is the ability for HeyGears 3D printers to isolate exposure times to different regions of each layer. This ensures maximum detail and dimensional accuracy of the part, maximum strength of support structures whilst maintaining minimal peeling force between layers.

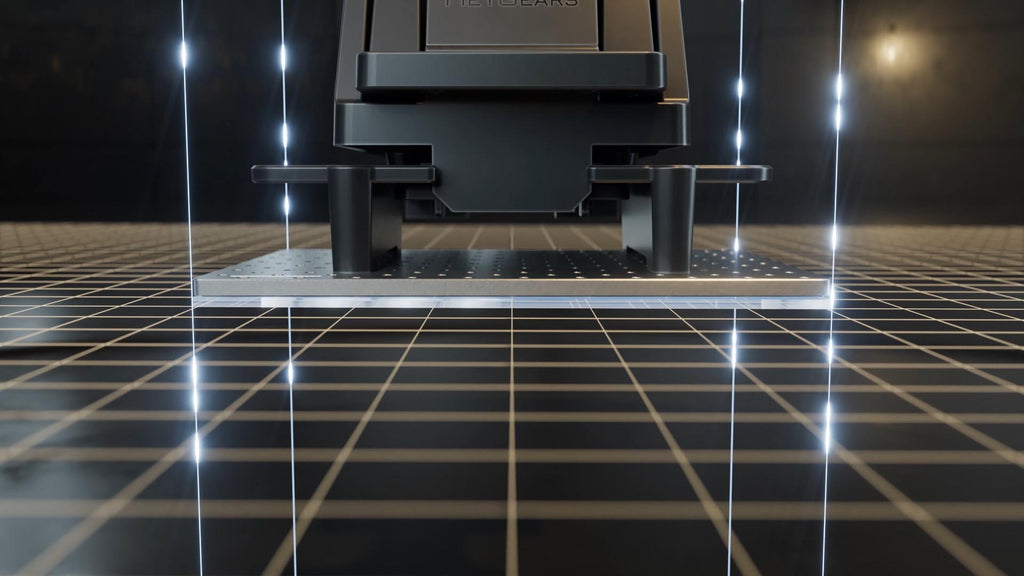

The UltraCraft Reflex Combo is easy to set up and start printing, with Intelligent assisted leveling and a floating screen structure, Reflex can automatically level build plate inclinations of up to 0.15° and eliminate gaps between the platform and tray of up to 150 μm.

Ideal for the production of batch production of consumer products. The UltraCraft Reflex Combo can achieve repeatable production of identical parts.

UltraCraft Wash is linked via Wi-Fi through the Blueprint print management software ensuring the wash cycle is optimised for the resin material used in the print cycle.

The wash motion systems ensures minimal contact with resin offers 15% more cleaning efficiency and is 1.5 times more effective washing than competitor products and is specifically designed for the Reflex one-stop production platform. Its efficient vibration-based deep cleaning achieves better final results.

UltraCraft Cure features dual UV wavelength 405 + 365 nm final curing combined with a heating function.

Heating and curing cycles are set and managed automatically through the Blueprint slicing software via Wi-Fi ensuring optimal mechanical properties are achieved based on the materials used.

The UltraCraft Reflex can achieve ultra fine detail and is able to print details as precise as 0.136 mm

Better than injection molding dimensional accuracy

Ideal for the production parts and prototyping the UltraCraft Reflex can achieve Zero Tolerance fitment of mating parts.

*Test with UltraPrint PARP10 Rapid Prototyping Resin