Your Cart is Empty

We gladly accept school purchase orders!

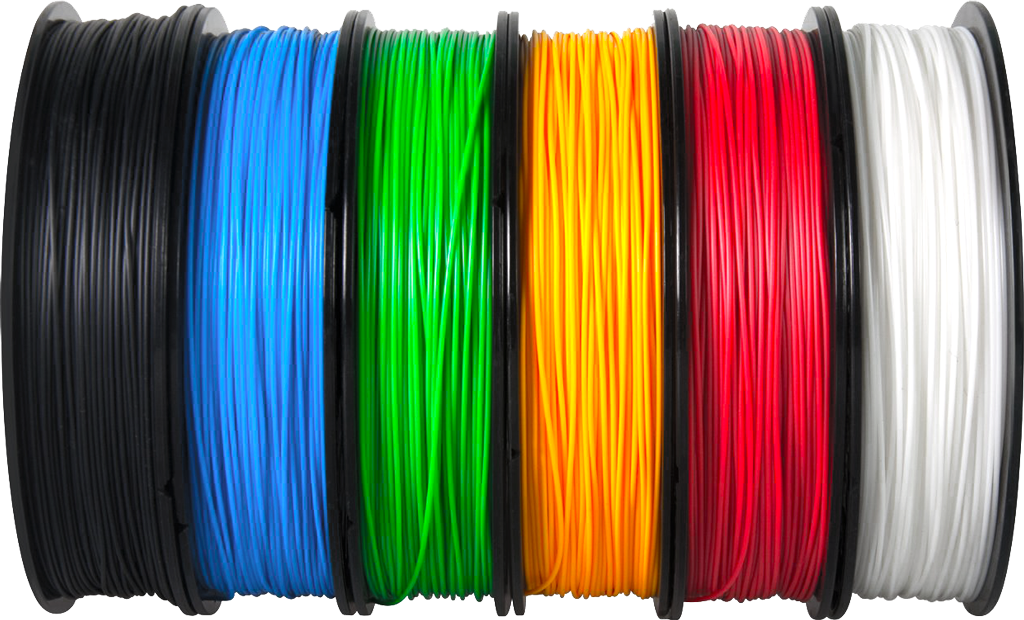

Buy a 6 pack and Save! Package includes one of each colour!

Up Fila ABS 3D Filament is exceptional quality 3D printing filament engineered Tiertime, the makers of Up 3D printers. This unique material formula which contains Polycarbonate offers higher strength and low warp characteristics with a slightly glossy finish. It has a low odor to standard ABS and prints at a higher temperature of up to 273°C.

This ABS+filament is made to high dimensional tolerances and printed parts present high detail in a fine surface finish. It is tough and durable and easily sanded and painted with acrylic paints and primers. Models can be glued with superglue, epoxy of ABS cement. Additionally parts can be combines with a solvent such as acetone of MEK (methyl ethyl ketone)

This premium ABS blended filament has materiel and mechanical characteristics to professional FDM printers at less than a quarter of their price. So it offers great offers great value.

Up Fila ABS has been engineered to work with Up 3D Printers by Tiertime. We have extensively tested this material which also performs excellently on other ABS compatible 3d printers.

The filament comes on 500 gram spools and fits onto the Up Mini Filament Bunker as well as all other Up 3D printers by Tiertime.

Filament Diameter: 1.75mm +- 0.1mm

Spool Size: 500grams

Filament length: 200 meters on each roll

Supplied in a vacuum packed foil bag with desiccant

Printing Temperature 230-270°C (260°C recommended)

Heated Bed Temperature: 80 -110°C (recommended)

Formula: Low odour ABS / Polycarbonate Blend

For optimal printing results using Up Fila ABS 3D Filaments we recommend printing this material on a 3d printer with an enclosure without drafts and a heated bed. Additionally where possible avoid air to blow over the nozzle area.

The ideal temperature for the heatbed and enclose can vary depending on the part you wish to print. There is a trade off between ambient temperature and the quality of the print results. A hotter environment results slower more even cooling of the part as it prints which reduces the tendency to warp. The trade off is that the quality of underside surfaces may be compromised as filament may still be molten and unstable when the next layer of filament is formed. The advantage of Up Fila ABS filament is the fact that it remains stable at a higher temperature and thus more stable- resulting with a better print quality and less warping. If you are trying to print very small parts the head radiating from the nozzle may prevent the filament to solidify the part in time for the next layer. A pro tip here is to print multiple items a distance apart from each other. This gives each part enough time to solidify whilst the nozzle has moved away to print elsewhere.

There are all types of methods people use to assist adhesion, everyone has their personal preference. If printing on glass. We have found that an ABS slurry is the strongest for ABS printed parts. Dissolve scarps of ABS filament into acetone to form a slurry the consistency of milk. Apply a very think layer on the print surface, avoid inhalation and do not contact your skin. (Not recommended in school environments an not necessary to use with an Up Printer as the perforated board is very effective at adhering prints)

1. Clean the print bed surface with a rubbing alcohol such as isopropyl or acetone (avoid contact with skin).

2. Ensure the nozzle is clean from any debris prior to printing. Heat the nozzle to full printing temperature and use a wire brush. Work you way around the nozzle tip avoiding deforming the hole where to filament comes out. This will avoid your model from being contaminated with charred material during the print.

3. Check that the nozzle height calibration is correct. If a print does not stick, it is because the nozzle height is not calibrated.

4. Optimal bed and enclosure temperature depends on the part you wish to print. As a rule of thumb, a smaller part have less tendency to warp and has less time to stablise before the next layer is formed, so print it with a lower bed/enclosure temperature to ensure the best surface finish- say a bed temperature of 80-90°C and 40- 50°C for the enclosure for a small parts. If you are printing large parts use a higher bed temperature of 90-110°C and an enclosure of around 60°C.

5. If you are printing a large part pre-heated bed for 30 to 60 minutes prior to starting the build. This will warm the enclosure as well as ensure that the heated bed surface has an even heat distribution. If you start a print as soon as the bed reached temperature, the bed will still be cold on the edges. As the bed heats us whilst your part is printing, the bed will keep heat (and expanding) which will laminate your part from the bed and curl on the edges.

You can make ABS 3d printed parts stronger, air tight and smooth using this method. This method used acetone which is high toxic so be aware of cautious and do so at your own risk!